Kab Ntau Lawm Margarine Rau Khoom Noj Qab Zib

Kab Ntau Lawm Margarine Rau Khoom Noj Qab Zib

Kab Ntau Lawm Margarine Rau Khoom Noj Qab Zib

Yees duab tsim tawm:https://www.youtube.com/watch?v=3cSJknMaYd8

Lub khw muag khoom noj kab ntau lawm margarineMuaj ntau theem los hloov cov khoom siv raw mus ua cov khoom muaj roj emulsified uas nthuav tau. Hauv qab no yog cov ntsiab lus tseem ceeb thiab cov txheej txheem hauv cov kab tsim margarine:

1. Kev Npaj Khoom Siv Raw

Kev Sib Xyaws Roj & Cov Rog– Cov roj zaub (xibtes, taum pauv, paj noob hlis, noob paj noob hlis) yog cov roj uas tau ua kom huv, dawb, thiab tshem tawm cov ntxhiab tsw (RBD). Cov roj tawv (xws li xibtes stearin) yuav raug ntxiv rau kom muaj cov qauv zoo nkauj.

- Kev Sib Tov Khoom Ua Dej– Dej, ntsev, cov tshuaj emulsifiers (lecithin, mono/diglycerides), cov tshuaj preservatives (potassium sorbate), thiab cov tshuaj tsw qab tau npaj lawm

2. Kev sib xyaw ua ke

Cov roj thiab dej theem sib xyaw ua ke hauv ib qholub tank emulsificationnrog cov khoom sib xyaw ua ke siab los tsim cov khoom ua ntej emulsion ruaj khov (dej-hauv-roj).

Qhov piv txwv ib txwm muaj80% rog, 20% dej (tej zaum yuav txawv rau cov roj tsawg).

3. Kev Siv Tshuaj Tua Kab Mob (Kev Kho Mob Kub)

- Cov emulsion yog rhuab rau~70–80°Cnyob rau hauv lub phaj hloov pauv cua sov kom tua cov kab mob thiab xyuas kom meej tias muaj kev sib npaug.

4. Kev Txias & Crystallization (Votator System)

Cov margarine hla dhau ib qhoCov cua sov sib pauv saum npoo av (SSHE)los yogtus neeg pov npav, qhov twg nws txias sai sai kom ua rau cov rog crystallization:

- Ib Chav (Lub Tog Txias): Supercooling rau4–10°Ctsim cov roj me me uas muaj cov khoom siv roj.

- Chav B (Tus neeg ua haujlwm Pin): Ua haujlwm sib tov ua kom cov qauv du thiab plasticity.

- Lub raj so (C Chav): Tso cai rau crystal stabilization.

5. Ntim Khoom

- Cov tshuab sau margarinefaib cov margarine rau hauv cov thoob, cov ntawv qhwv (rau cov margarine lo), lossis cov thawv loj.

- Kev Sau Npe & Kev Sau Code: Cov ntsiab lus ntawm cov khoom thiab cov lej batch tau luam tawm.

6. Kev Tshawb Xyuas Kev Tswj Xyuas Zoo

- Kev ntxhib los mos thiab kev nthuav dav(kev nkag mus).

- Melting Point(kom ntseeg tau tias ruaj khov ntawm chav tsev kub).

- Kev Nyab Xeeb ntawm Cov Kab Mob Me Me(tag nrho cov phaj, poov xab / pwm).

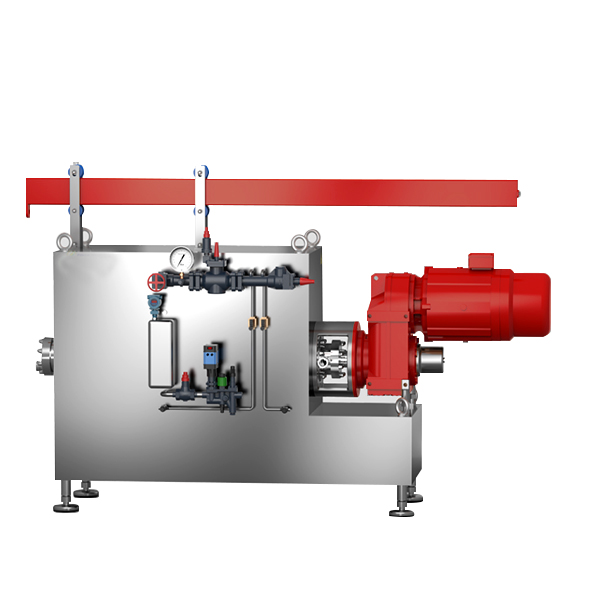

Cov Khoom Siv Tseem Ceeb hauv Kab Margarine

| Cov khoom siv | Kev Ua Haujlwm |

| Lub tank emulsification | Sib xyaw cov roj / dej theem |

| Phaj Kub Exchanger | Ua kom cov emulsion qhuav |

| Lub Tshuab Hloov Kub Uas Tau Muab Tso Rau Hauv Qhov Chaw (Votator) | Txias sai & crystallization |

| Tus Neeg Ua Haujlwm Pin (Chav B) | Cov margarine ua rau cov qauv zoo nkauj |

| Cov Tshuab Ntim Khoom Thiab Ntim Khoom Rau Margarine | Cov khoom faib rau hauv cov chaw muag khoom |

Hom Margarine Uas Tsim Tawm

- Puff Pastry Margarine: Muaj zog heev, muaj ntau txheej

- Margarine ncuav mog qab zib: creamy, zoo aeration

- Margarine dov rau hauv: Lub ntsiab lus yaj siab rau lamination

- Margarine rau Kev Ua Noj Ua Haus Txhua Lub Hom Phiaj: Sib npaug rau ntau yam kev siv

Cov Kev Hloov Pauv Siab Tshaj Plaws

- Cov Margarine Uas Tsis Muaj TransSiv cov roj inter-esterified es tsis txhob siv cov hydrogenation ib nrab.

- Margarine Uas Muaj Cov Nroj Tsuag: Cov mis tsis muaj mis nyuj (rau cov khw muag khoom vegan).

Kev Ua Haujlwm ntawm Qhov Chaw