Kab Ntau Lawm Custard Sauce

Kab Ntau Lawm Custard Sauce

Kab Ntau Lawm Custard Sauce

Yees duab tsim tawm:https://www.youtube.com/watch?v=AkAcycJx0pI

Ibkab ntau lawm ntawm cov kua ntses custardMuaj ntau yam txheej txheem ua haujlwm tsis siv neeg thiab ib nrab tsis siv neeg los tsim cov kua ntses custard kom zoo, sib xws, thiab huv si. Hauv qab no yog cov kauj ruam yooj yim ntawm cov kab tsim cov kua ntses custard:

1. Kev Tswj thiab Kev Npaj Cov Khoom Xyaw

- Kev Txais Mis Nyuj thiab Kev Khaws Cia

- Tau txais cov mis nyuj nyoos, kuaj seb puas zoo, thiab khaws cia rau hauv lub silos txias.

- Lwm txoj kev xaiv: Mis nyuj hmoov + dej uas tau sib xyaw ua ke (kom khaws tau ntev dua).

- Kev Tswj Xyuas Qab Zib & Cov Khoom Qab Zib

- Cov suab thaj, cov kua txiv pob kws, lossis lwm yam khoom qab zib raug ntsuas thiab yaj.

- Kev Ua Qe & Hmoov Qe

- Cov qe ua kua (pasteurized) los yog hmoov qe yog sib xyaw nrog dej.

- Hmoov txhuv nplej siab thiab cov khoom ruaj khov

- Cov hmoov txhuv nplej siab, cov hmoov txhuv nplej siab hloov kho, lossis cov khoom ua kom tuab (piv txwv li, carrageenan) raug sib xyaw ua ntej kom tsis txhob sib sau ua ke.

- Cov Tshuaj Tsw Qab thiab Cov Khoom Ntxiv

- Vanilla, caramel, lossis lwm yam tsw qab, nrog rau cov tshuaj preservatives (yog tias xav tau), raug npaj.

2. Kev Sib Tov & Kev Sib Xyaws

- Kev Sib Tov Ua Ib Ke Los Yog Kev Sib Tov Nruam

- Cov khoom xyaw tau muab sib xyaw ua ke hauv ib qholub tshuab sib tov high-shearlos yoglub tank ua ntej sib tovnyob rau hauv qab qhov kub thiab txias uas tswj tau (kom tsis txhob ua kom tuab ua ntej lub sijhawm).

- Kev sib xyaw ua ke tuaj yeem siv rau kev ua kom homogeneous.

3. Ua Noj & Ua Kom Pasteurization

- Kev Ua Noj Txuas Ntxiv (Scraped Surface Heat Exchanger)

- Cov sib tov yog cua sov rau75–85°C (167–185°F)kom ua kom cov hmoov txhuv nplej siab gelatinization thiab ua kom cov kua ntses tuab.

- Kev ua kom qhuav (HTST lossis Batch)

- Kub Siab Lub Sijhawm Luv (HTST) ntawm72°C (161°F) rau 15-20 vib nas thislos yog ua kom cov kab mob me me muaj kev nyab xeeb.

- Theem Txias

- Txias sai rau4–10°C (39–50°F)kom tsis txhob ua noj ntxiv thiab tswj tau qhov zoo nkauj.

4. Kev Sib Xyaws (Xaiv Tau)

- Lub Tshuab Homogenizer Siab

- Siv rau cov qauv du heev (tiv thaiv kom tsis txhob muaj cov noob).

5. Kev Sau thiab Ntim Khoom

- Tsis Siv Neeg Sau Cov Tshuab

- Kev ntim hnab(rau kev muag khoom) los yogkev ntim khoom ntau(rau kev pabcuam zaub mov).

- Kev txhaws tsis muaj kab mob(rau lub sijhawm khaws cia ntev) lossissau kub(rau kev cia khoom ib puag ncig).

- Cov Hom Ntawv Ntim Khoom:

- Cov fwj yas, cov thawv ntawv, cov hnab yas, lossis cov kaus poom.

- Kev siv cov pa nitrogen los ntxuav yuav siv tau los ua kom lub sijhawm khaws cia ntev dua.

6. Kev Txias thiab Kev Khaws Cia

- Kev Siv Tshuaj Tua Kab Mob (yog tias xav tau)

- Rau cov custard txias, txias sai rau4°C (39°F).

- Kev Khaws Cia Txias

- Khaws cia rau ntawm4°C (39°F)rau cov custard tshiab lossis ambient rau cov khoom kho UHT.

7. Kev Tswj Xyuas Zoo & Kev Ntsuas

- Kev Tshawb Xyuas Viscosity(siv cov viscometers).

- Kev Saib Xyuas pH(lub hom phiaj: ~6.0–6.5).

- Kev Ntsuas Kab Mob Me Me(tag nrho cov phaj, poov xab / pwm).

- Kev Ntsuam Xyuas Kev Xav(saj, qauv, xim).

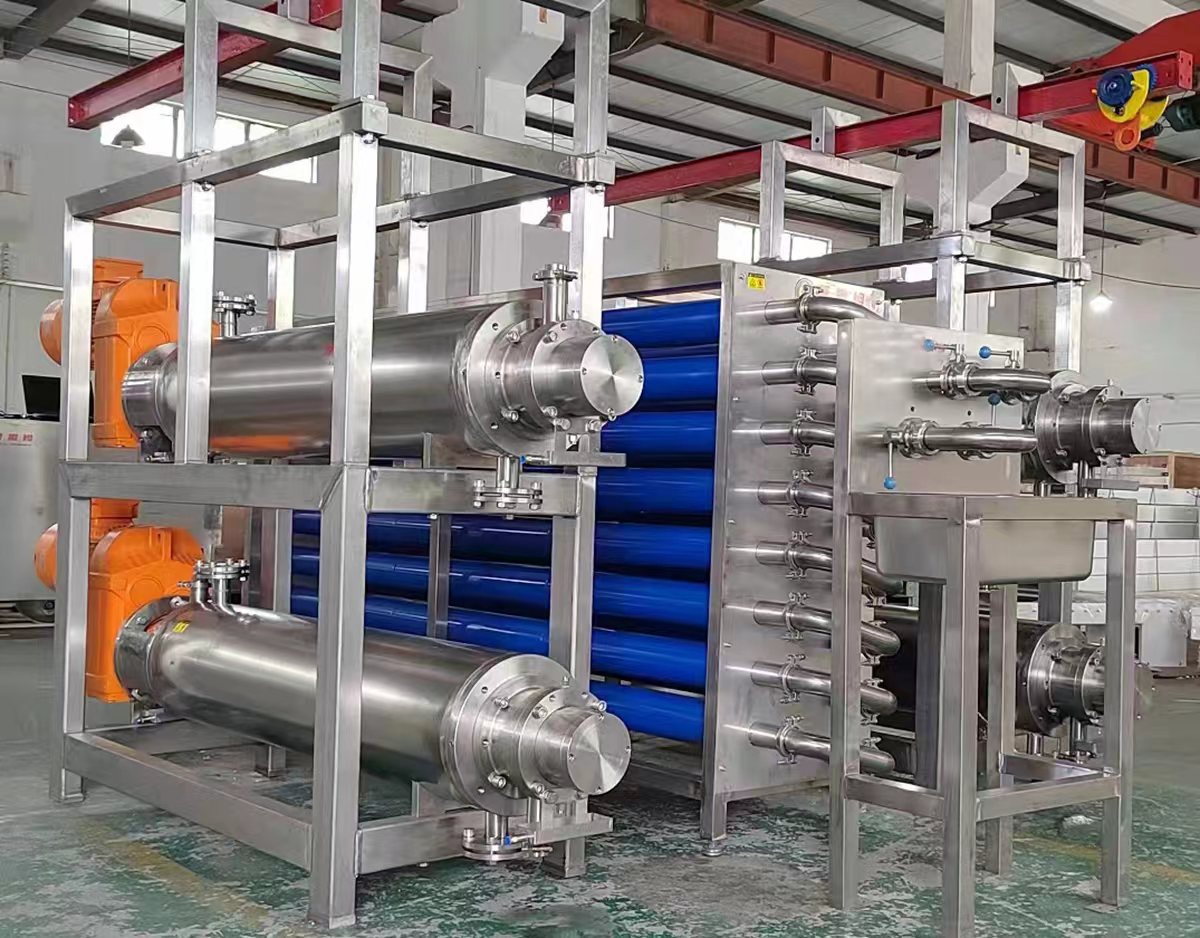

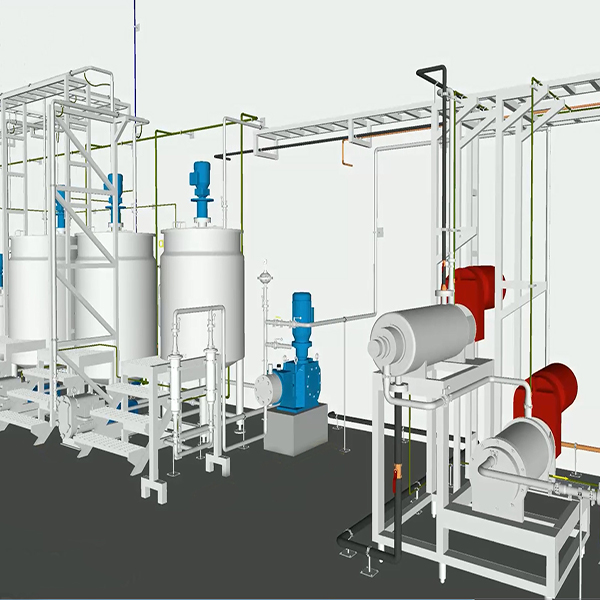

Cov Khoom Siv Tseem Ceeb hauv Kab Tsim Khoom Custard Sauce

- Cov Thawv Cia Khoom(rau mis nyuj, cov khoom xyaw kua).

- Cov Txheej Txheem Ntsuas thiab Dosing.

- Cov Tov Khoom Siv High-Shear & Premix Tanks.

- Pasteurizer (HTST los yog Batch).

- Lub Tshuab Hloov Kub Uas Tau Muab Tso Rau Saum Nto (rau kev ua noj).

- Homogenizer (xaiv tau).

- Cov Tshuab Sau (piston, volumetric, lossis aseptic).

- Cov Qhov Dej Txias.

- Cov Tshuab Ntim Khoom (sealing, labeling).

Hom Custard Sauce Uas Tsim Tawm

- Custard txias(lub sijhawm khaws cia luv luv, saj tshiab).

- UHT Custard(lub sijhawm khaws cia ntev, sterilized).

- Hmoov Custard Sib Xyaws(rau kev tsim dua tshiab).

Kev Siv Tshuab thiab Kev Ua Haujlwm Zoo

- PLC Tswj Cov Tshuabrau qhov kub thiab txias meej thiab kev sib tov.

- CIP (Ntxuav-Hauv-Qhov Chaw) Cov Txheej Txheemrau kev tu cev.

Kev Ua Haujlwm ntawm Qhov Chaw

Sau koj cov lus ntawm no thiab xa tuaj rau peb