Margarine Production Technology

EXECUTIVE SUMMARY

Cov tuam txhab khoom noj niaj hnub no zoo li lwm cov lag luam tsim khoom lag luam tsis yog tsom rau kev ntseeg siab thiab zoo ntawm cov khoom siv ua zaub mov tab sis kuj muaj ntau yam kev pab cuam uas tus neeg muag khoom ntawm cov khoom siv tuaj yeem xa tuaj. Sib nrug los ntawm cov kab ua haujlwm tau zoo uas peb xa tuaj, peb tuaj yeem ua tus khub los ntawm thawj lub tswv yim lossis qhov project theem mus rau theem kawg commissioning, tsis txhob hnov qab txog qhov tseem ceeb tom qab kev lag luam kev pabcuam.

Shiputec muaj ntau tshaj 20 xyoo kev paub rau kev ua zaub mov thiab ntim kev lag luam.

INTRODUCTION RAU PEB TECHNOLOGY

VISION THIAB COMITMENT

Shiputec ntu tsim, tsim khoom thiab kev lag luam txheej txheem engineering thiab automation kev daws teeb meem rau cov khoom noj siv mis, khoom noj, dej haus, dej hiav txwv, kev lag luam tshuaj thiab kev saib xyuas tus kheej los ntawm nws cov haujlwm thoob ntiaj teb.

Peb tau cog lus los pab peb cov neeg siv khoom thoob plaws ntiaj teb los txhim kho kev ua tau zoo thiab muaj txiaj ntsig ntawm lawv cov chaw tsim khoom thiab cov txheej txheem. Peb ua tiav qhov no los ntawm kev muab ntau yam khoom lag luam thiab cov kev daws teeb meem los ntawm cov khoom tsim kho los tsim cov txheej txheem ua tiav cov nroj tsuag txhawb nqa los ntawm cov ntawv thov thoob ntiaj teb thiab kev tsim kho kev txawj ntse.

Peb txuas ntxiv pab peb cov neeg siv khoom txhim kho kev ua tau zoo thiab muaj txiaj ntsig ntawm lawv cov nroj tsuag thoob plaws hauv nws lub neej kev pabcuam nrog cov kev pabcuam txhawb nqa raws li lawv tus kheej xav tau los ntawm kev sib koom ua haujlwm pabcuam cov neeg siv khoom thiab cov khoom seem.

CUSTOMER FOCUS

Shiputec tsim, tsim thiab txhim kho cov khoom siv niaj hnub, ua haujlwm zoo thiab txhim khu kev qha rau kev lag luam khoom noj. Rau kev tsim cov khoom siv roj crystallized xws li margarine, butter, kis thiab luv luv Shiputec muaj cov kev daws teeb meem uas tseem suav nrog cov txheej txheem rau cov khoom noj emulsified xws li mayonnaise, kua ntses thiab hnav khaub ncaws.

MARGARINE PRODUCTION

Margarine thiab cov khoom lag luam muaj feem xyuam nrog cov dej theem thiab theem roj thiab tuaj yeem ua tau raws li dej-hauv-roj (W / O) emulsions nyob rau hauv uas cov dej theem yog finely dispersed raws li tee nyob rau hauv lub nruam rog theem. Nyob ntawm daim ntawv thov ntawm cov khoom, muaj pes tsawg leeg ntawm cov roj theem thiab cov txheej txheem raug xaiv raws li.

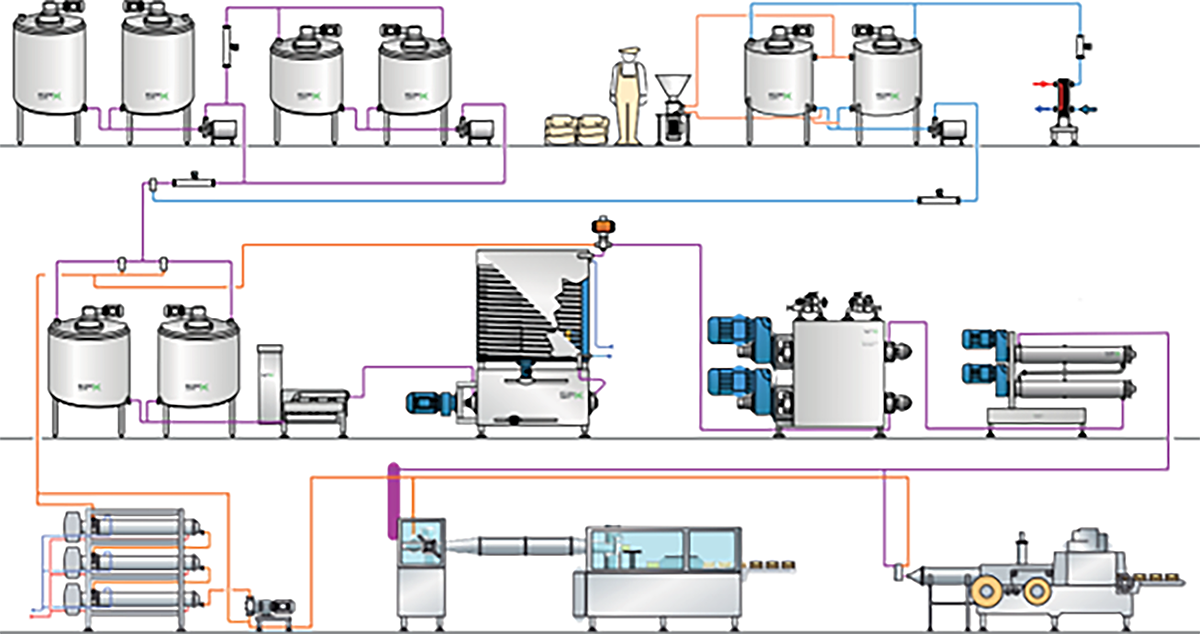

Sib nrug los ntawm cov khoom siv crystallization, lub chaw tsim khoom niaj hnub rau margarine thiab cov khoom lag luam feem ntau yuav suav nrog ntau lub tso tsheb hlau luam rau cov roj cia nrog rau emulsifier, dej theem thiab kev npaj emulsion; qhov loj thiab tus naj npawb ntawm cov tso tsheb hlau luam raug xam raws li lub peev xwm ntawm cov nroj tsuag thiab cov khoom lag luam. Lub chaw tseem muaj xws li chav tsev pasteurization thiab lub chaw remelting. Yog li, cov txheej txheem tsim khoom feem ntau tuaj yeem muab faib ua cov txheej txheem hauv qab no (thov saib daim duab 1):

KEV PAB CUAM NTAWM E WATER PHASE THIAB KEV PHEM (ZEEM 1)

Cov theem dej feem ntau yog npaj batch-wise nyob rau hauv cov dej theem tank. Cov dej yuav tsum yog cov dej haus zoo. Yog tias haus dej tsis zoo tuaj yeem lav tsis tau, cov dej tuaj yeem raug kho ua ntej los ntawm kev siv xws li UV lossis lim dej.

Sib nrug los ntawm cov dej, cov dej theem tuaj yeem muaj ntsev los yog brine, mis nyuj proteins (cov lus margarine thiab cov rog tsawg), qab zib (puff pastry), stabilizers (txo thiab tsis muaj roj kis), preservatives thiab dej-soluble flavors.

Cov khoom xyaw tseem ceeb hauv theem rog, cov rog sib xyaw, feem ntau yog sib xyaw ntawm cov rog sib txawv thiab cov roj. Txhawm rau ua tiav margarine nrog cov yam ntxwv xav tau thiab kev ua haujlwm, qhov sib piv ntawm cov roj thiab cov roj hauv cov roj sib tov yog txiav txim siab rau kev ua haujlwm ntawm cov khoom kawg.

Cov roj ntau thiab roj, xws li roj sib xyaw lossis roj ib leeg, yog khaws cia hauv cov roj cia tank feem ntau muab tso rau sab nraum qhov chaw tsim khoom. Cov no tau khaws cia ntawm qhov ntsuas kub ruaj khov siab tshaj qhov melting point ntawm cov roj thiab nyob rau hauv agitation kom tsis txhob fractionation ntawm cov roj thiab cia yooj yim tuav.

Sib nrug los ntawm cov rog sib xyaw, cov roj theem feem ntau muaj cov khoom xyaw roj-soluble me xws li emulsifier, lecithin, tsw, xim thiab antioxidants. Cov khoom me me no tau yaj hauv cov roj sib xyaw ua ntej cov dej theem ntxiv, yog li ua ntej cov txheej txheem emulsification.

EMULSION Kev Npaj (ZONE 2)

Lub emulsion yog npaj los ntawm kev hloov ntau yam roj thiab roj los yog roj sib xyaw rau hauv lub tank emulsion. Feem ntau, cov roj melting siab lossis cov roj sib tov yog ntxiv ua ntej los ntawm cov roj melting qis thiab cov roj ua kua. Txhawm rau ua kom tiav qhov kev npaj ntawm cov roj theem, cov emulsifier thiab lwm cov khoom xyaw roj-soluble me yog ntxiv rau cov roj sib tov. Thaum tag nrho cov khoom xyaw rau theem rog tau raug muab sib xyaw kom zoo, cov theem dej ntxiv thiab cov emulsion yog tsim nyob rau hauv hnyav tab sis tswj kev sib xyaw.

Cov tshuab sib txawv tuaj yeem siv los ntsuas qhov sib txawv ntawm cov khoom xyaw rau emulsion uas ob ua haujlwm batch-wise:

Flow Meter system

Qhov hnyav tank system

Ib qho kev txuas ntxiv hauv-kab emulsification system yog qhov tsis nyiam tab sis siv cov tshuaj hauv xws li cov kab muaj peev xwm siab uas txwv qhov chaw rau emulsion tso tsheb hlau luam. Lub kaw lus no yog siv cov twj tso kua mis thiab cov ntsuas dej loj los tswj qhov sib piv ntawm cov theem ntxiv rau hauv lub tank me me emulsion.

Cov tshuab uas tau hais los saum toj no tuaj yeem tswj tau tag nrho. Qee cov nroj tsuag laus, txawm li cas los xij, tseem muaj cov txheej txheem tswj kev tswj hwm emulsion tab sis cov no yog cov neeg xav tau kev ua haujlwm thiab tsis pom zoo rau nruab hnub no vim yog cov cai nruj heev.

Flow meter system yog raws li kev npaj batch-wise emulsion nyob rau hauv uas ntau theem thiab cov khoom xyaw yog ntsuas los ntawm huab hwm coj ntsuas ntsuas thaum hloov los ntawm ntau theem npaj tso tsheb hlau luam rau hauv lub tank emulsion. Qhov tseeb ntawm qhov system no yog +/- 0.3%. Qhov system no yog tus cwj pwm los ntawm nws qhov tsis txaus ntseeg rau sab nraud cuam tshuam xws li kev vibrations thiab av.

Lub cev hnyav lub tank zoo li lub ntsuas dej ntws raws li kev npaj batch-wise emulsion. Ntawm no cov nqi ntawm cov khoom xyaw thiab cov theem yog ntxiv ncaj qha rau lub tank emulsion uas yog mounted rau load hlwb tswj cov nyiaj ntxiv rau lub tank.

Feem ntau, ob lub tank yog siv los npaj cov emulsion thiaj li yuav khiav tau cov kab crystallization tsis tu ncua. Txhua lub tank ua haujlwm raws li kev npaj thiab tsis tank (emulsion tank), yog li cov kab crystallization yuav raug pub los ntawm ib lub tank thaum lub batch tshiab yuav npaj rau lwm qhov thiab vice versa. Qhov no yog hu ua flip-flop system.

Ib qho kev daws teeb meem uas cov emulsion tau npaj rau hauv ib lub tank thiab thaum npaj tau hloov mus rau lub tank tsis los ntawm qhov chaw uas cov kab crystallization tau pub kuj yog ib qho kev xaiv. Qhov system no hu ua premix/buffer system.

PASTEURIZATION (ZONE 3)

Los ntawm lub tank buffer lub emulsion yog ib txwm tsis tu ncua pumped los ntawm ib tug phaj kub exchanger (PHE) los yog ib tug tsis tshua muaj siab scraped nto tshav kub exchanger (SSHE), los yog siab SSHE rau pasteurization ua ntej nkag mus rau hauv lub crystallization kab.

Rau cov khoom lag luam rog tag nrho PHE feem ntau yog siv. Rau cov roj qis dua qhov twg cov emulsion yuav tsum muaj cov viscosity siab heev thiab rau cov cua sov-sensible emulsions (xws li emulsions nrog cov ntsiab lus protein siab) SPX system raws li cov tshuaj tsis tshua muaj siab lossis SPX-PLUS raws li kev daws teeb meem siab.

Cov txheej txheem pasteurization muaj ntau qhov zoo. Nws ua kom inhibition ntawm cov kab mob kev loj hlob thiab kev loj hlob ntawm lwm cov kab mob, yog li txhim kho microbiological stability ntawm emulsion. Pasteurization ntawm cov dej theem tsuas yog ib qho ua tau, tab sis pasteurization ntawm tag nrho cov emulsion yog nyiam vim cov txheej txheem pasteurization ntawm emulsion yuav mini-mise lub sij hawm nyob los ntawm cov khoom pasteurized mus sau lossis ntim cov khoom kawg. Tsis tas li, cov khoom lag luam raug kho nyob rau hauv cov txheej txheem los ntawm pasteurization mus rau sau lossis ntim cov khoom kawg thiab pasteurization ntawm cov khoom siv rov ua dua tshiab tau lees paub thaum ua tiav emulsion yog pasteurized.

Tsis tas li ntawd, pasteurization ntawm tag nrho emulsion xyuas kom meej tias cov emulsion yog pub rau cov kab crystallization ntawm qhov kub thiab txias, ua tiav qhov kev ua haujlwm tas li, cov khoom kub thiab cov khoom zoo nkauj. Tsis tas li ntawd, qhov tshwm sim ntawm pre-crystallized emulsion pub rau cov khoom siv crystallization yog tiv thaiv thaum lub emulsion yog pasteurized zoo thiab pub rau lub twj tso kua mis siab ntawm qhov kub ntawm 5-10 ° C siab tshaj qhov melting point ntawm cov roj theem.

Cov txheej txheem pasteurization ib txwm yuav tom qab kev npaj ntawm emulsion ntawm 45-55 ° C suav nrog cua sov thiab tuav ib ntus ntawm emulsion ntawm 75-85 ° C rau 16 sec. Thiab tom qab ntawd cov txheej txheem txias rau qhov kub ntawm 45-55 ° C. Qhov kawg kub nyob ntawm qhov melting point ntawm cov roj theem: qhov siab dua qhov melting point, qhov kub thiab txias.

Chilling, CRYSTALLIZATION thiab KNEADING (ZONE 4)

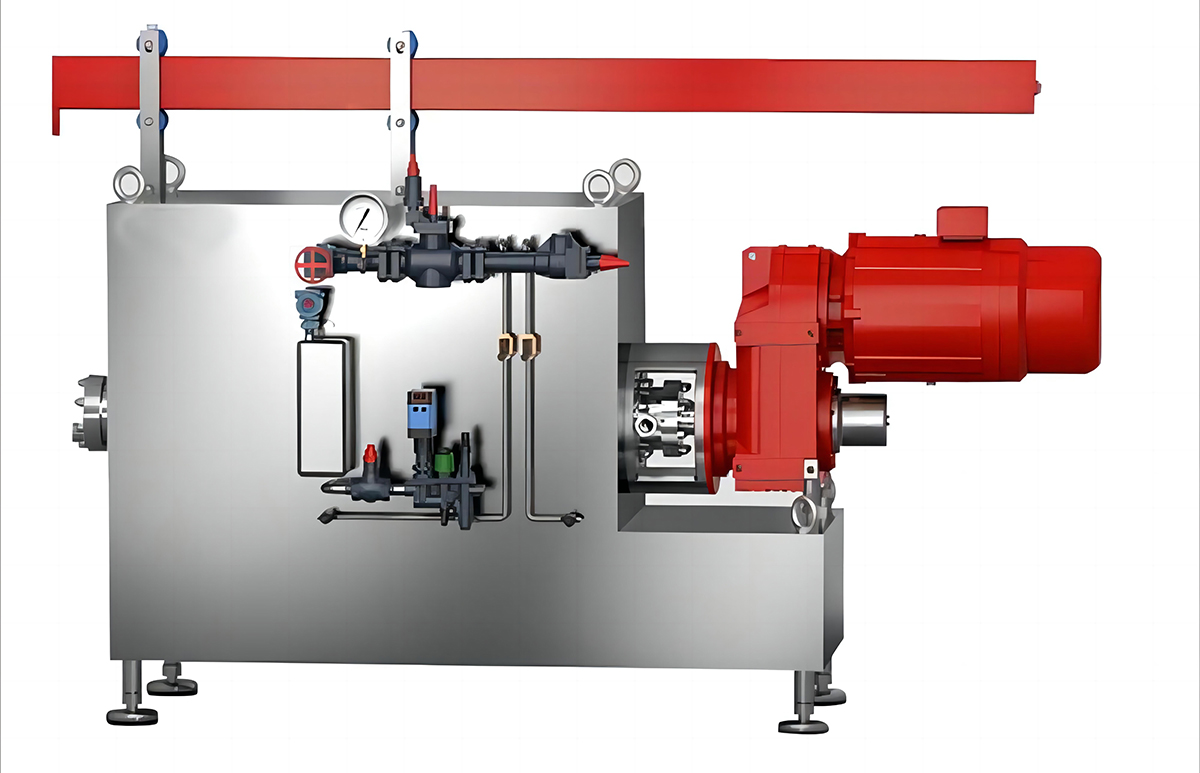

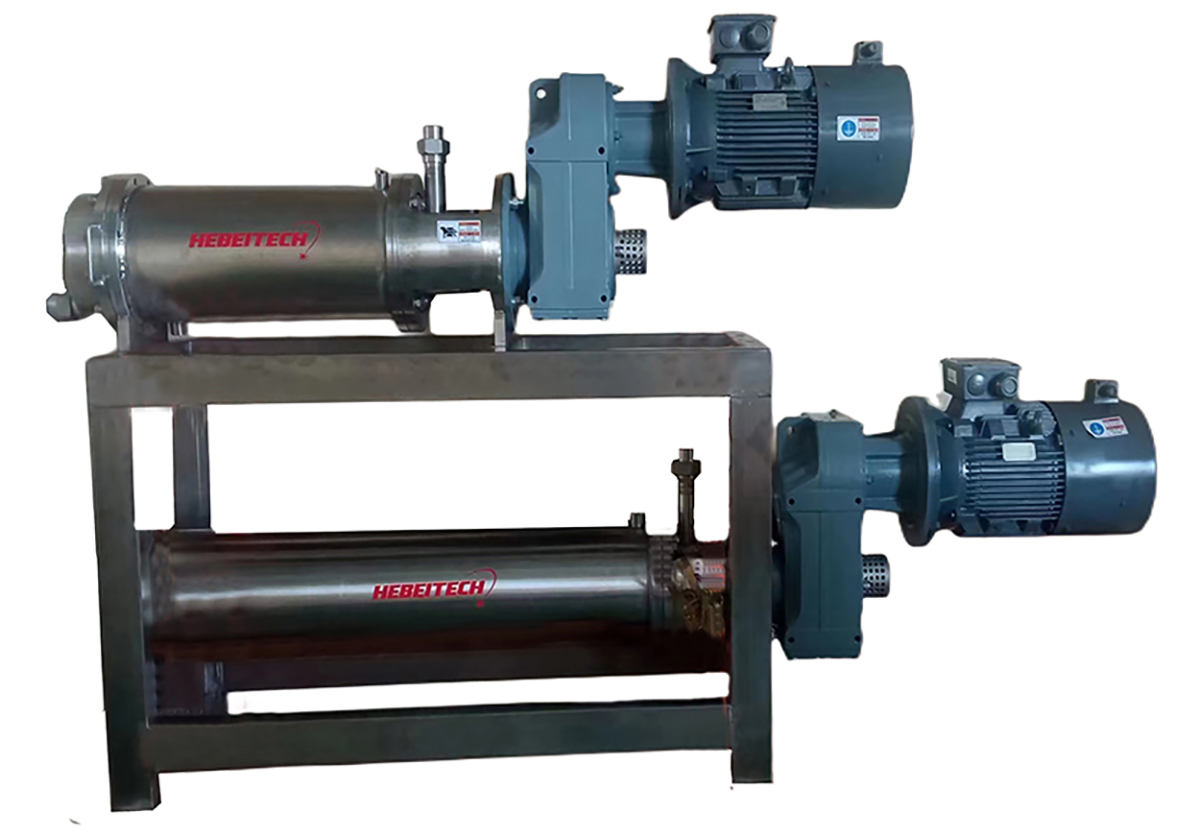

Lub emulsion yog pumped rau cov kab crystallization los ntawm kev siv lub twj tso kua mis siab piston (HPP). Cov kab crystallization rau kev tsim cov margarine thiab cov khoom muaj feem cuam tshuam feem ntau muaj lub siab SSHE uas yog txias los ntawm ammonia lossis Freon hom cua txias. Pin rotor tshuab (s) thiab/los yog nruab nrab crystallizers feem ntau muaj nyob rau hauv kab thiaj li yuav ntxiv kneading siv thiab sij hawm rau zus tau tej cov khoom yas. Lub raj so yog cov kauj ruam kawg ntawm cov kab crystallization thiab tsuas yog suav nrog yog tias cov khoom ntim khoom.

Lub plawv ntawm cov kab crystallization yog lub siab SSHE, uas lub emulsion sov yog super-cooled thiab crystallized nyob rau hauv lub puab nto ntawm lub chilling raj. Lub emulsion yog zoo scraped tawm los ntawm cov rotating scrapers, yog li cov emulsion yog chilled thiab kneaded ib txhij. Thaum cov roj nyob rau hauv emulsion crystallizes, cov roj muaju ua rau peb-dimensional network entrapping cov dej tee dej thiab cov roj ua kua, uas ua rau cov khoom uas muaj cov khoom ntawm cov khoom yas semi-solid xwm.

Nyob ntawm seb hom khoom tsim thiab hom roj siv rau cov khoom tshwj xeeb, kev teeb tsa ntawm cov kab crystallization (piv txwv li qhov kev txiav txim ntawm cov raj chilling thiab cov pin rotor tshuab) tuaj yeem hloov kho kom zoo tshaj plaws rau cov khoom tshwj xeeb.

Txij li cov kab crystallization feem ntau tsim ntau dua ib qho khoom siv roj, SSHE feem ntau muaj ob lossis ntau qhov txias txias los yog chilling raj txhawm rau ua kom tau raws li qhov yuav tsum tau ua rau txoj kab hloov pauv crystallization. Thaum tsim cov khoom sib txawv crystallized rog ntawm ntau cov roj sib xyaw, kev hloov pauv yog xav tau vim tias cov yam ntxwv crystallization ntawm cov khoom sib txawv yuav txawv ntawm ib qho mus rau lwm qhov.

Cov txheej txheem crystallization, cov txheej txheem ua haujlwm thiab cov txheej txheem ua haujlwm muaj kev cuam tshuam zoo rau cov yam ntxwv ntawm qhov kawg margarine thiab cov khoom sib kis. Thaum tsim cov kab crystallization, nws yog ib qho tseem ceeb los txheeb xyuas cov yam ntxwv ntawm cov khoom uas tau npaj los tsim rau ntawm kab. Txhawm rau tiv thaiv kev nqis peev rau yav tom ntej, kev hloov pauv ntawm txoj kab nrog rau kev tswj hwm tus kheej ntawm tus kheej yog qhov tsim nyog, vim tias ntau yam ntawm cov khoom txaus siab yuav hloov nrog lub sijhawm thiab cov ntaub ntawv raw.

Lub peev xwm ntawm cov kab yog txiav txim siab los ntawm qhov chaw txias muaj nyob ntawm SSHE. Cov tshuab loj sib txawv muaj xws li los ntawm cov kab qis mus rau siab muaj peev xwm. Tsis tas li ntawd ntau yam kev hloov pauv tau muaj los ntawm cov khoom siv ib leeg mus rau ntau lub raj kab, yog li cov kab ua tau yooj yim heev.

Tom qab cov khoom tau txias hauv SSHE, nws nkag mus rau lub tshuab pin rotor thiab / lossis nruab nrab crystallizers nyob rau hauv uas nws yog kneaded rau ib lub sij hawm ntawm lub sij hawm thiab nrog ib tug tej yam kev siv nyob rau hauv thiaj li yuav pab txhawb kev txhawb nqa ntawm peb-dimensional network, uas nyob rau theem macroscopic yog cov qauv yas. Yog tias cov khoom raug muab faib ua cov khoom qhwv, nws yuav nkag mus rau SSHE dua ua ntej nws nyob hauv lub raj so ua ntej qhwv. Yog tias cov khoom tau ntim rau hauv khob, tsis muaj lub raj so rau hauv cov kab crystallization.

PACKING, Filling thiab REMELTING (ZONE 5)

Ntau lub ntim thiab ntim tshuab muaj nyob rau hauv khw thiab yuav tsis tau piav qhia hauv tsab xov xwm no. Txawm li cas los xij, qhov sib xws ntawm cov khoom sib txawv heev yog tias nws yog tsim los ntim lossis ntim. Nws yog qhov pom tseeb tias cov khoom ntim khoom yuav tsum nthuav tawm qhov kev ntxhib los mos dua li cov khoom ntim thiab yog tias qhov kev ntxhib los mos tsis zoo, cov khoom yuav raug hloov mus rau cov txheej txheem remelting, melted thiab ntxiv rau lub tank tsis rau rov ua dua. Cov tshuab remelting sib txawv muaj tab sis cov tshuab siv feem ntau yog PHE lossis qis SSHE.

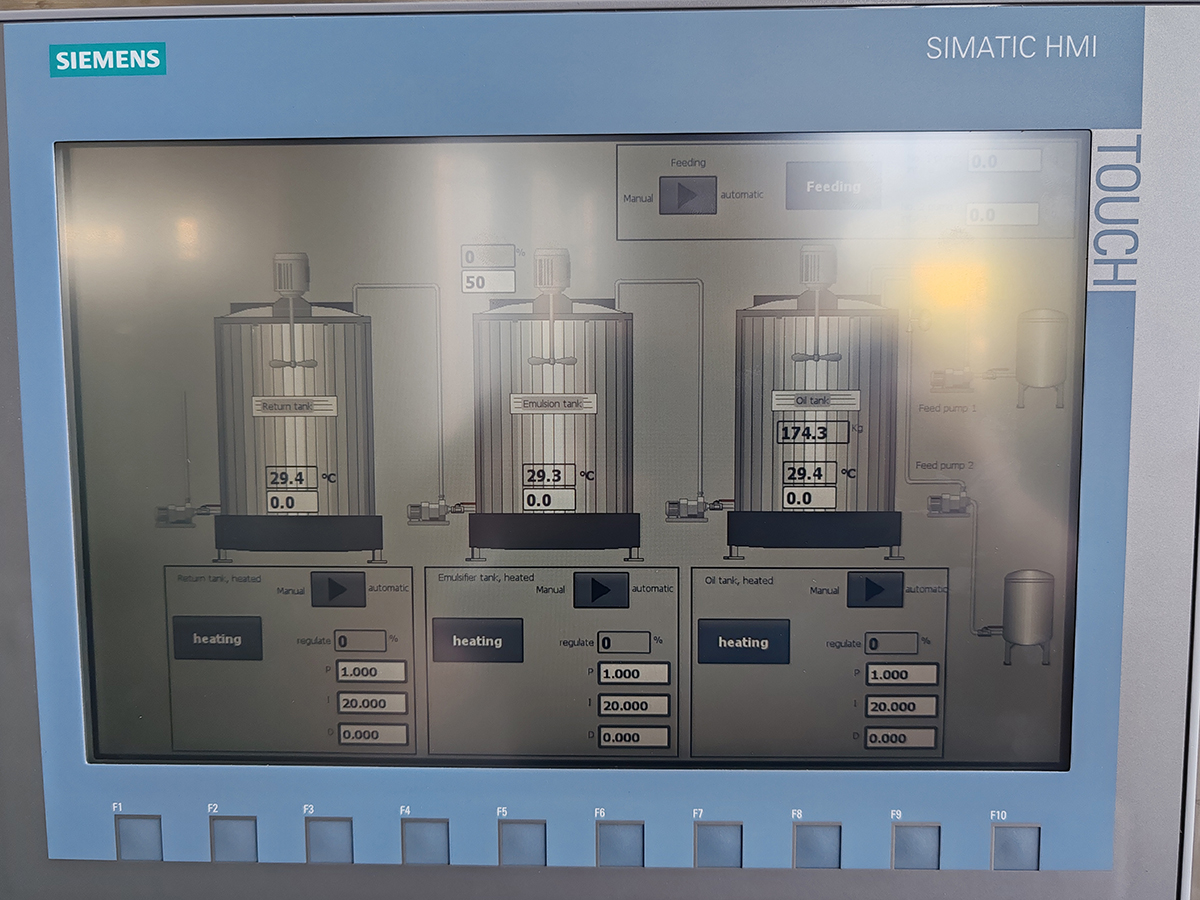

AUTOMATION

Margarine, zoo li lwm yam khoom noj khoom haus, yog nyob rau hauv ntau lub Hoobkas niaj hnub no tsim nyob rau hauv cov txheej txheem traceability nruj. Cov txheej txheem no feem ntau suav nrog cov khoom xyaw, kev tsim khoom thiab cov khoom kawg tshwm sim tsis yog hauv kev txhim kho khoom noj khoom haus xwb tab sis kuj nyob rau hauv cov zaub mov tsis tu ncua. Traceability xav tau tuaj yeem siv rau hauv kev tswj hwm ntawm lub Hoobkas thiab Shiputec tswj qhov system yog tsim los tswj, sau thiab sau cov xwm txheej tseem ceeb thiab tsis muaj feem cuam tshuam txog kev tsim khoom tiav.

Lub kaw lus tswj tau nruab nrog kev tiv thaiv lo lus zais thiab nta cov ntaub ntawv keeb kwm kev txiav txim siab ntawm txhua yam tsis muaj kev cuam tshuam rau hauv cov txheej txheem margarine los ntawm daim ntawv qhia cov ntaub ntawv mus rau qhov kawg ntawm cov khoom ntsuas. Cov ntaub ntawv logging suav nrog lub peev xwm thiab cov zis ntawm lub twj tso kua mis siab (l / teev thiab rov qab siab), cov khoom kub (nrog rau cov txheej txheem pasteurization) thaum lub sij hawm crystallization, txias txias (los yog txias xovxwm presses) ntawm SSHE, ceev ntawm SSHE thiab tus pin rotor cav tov nrog rau cov load ntawm motors khiav lub siab siab twj tso kua mis, lub SSHE thiab tus pin rotor tshuab.

Tswj qhov system

Thaum lub sij hawm ua, ceeb toom yuav raug xa mus rau tus neeg teb xov tooj yog tias cov kev ua tsis tau rau cov khoom tshwj xeeb tsis txwv; cov no yog teem rau hauv daim ntawv qhia editor ua ntej ntau lawm. Cov tswb no yuav tsum tau lees paub manually thiab ua raws li cov txheej txheem yuav tsum tau ua. Txhua lub tswb raug muab khaws cia rau hauv lub tswb moos keeb kwm kom pom tom qab. Thaum cov khoom tawm ntawm cov kab ntau lawm nyob rau hauv ib daim ntawv uas tsim nyog los yog sau daim ntawv, nws yog sib nrug los ntawm cov khoom npe feem ntau cim nrog hnub tim, lub sij hawm thiab batch identification naj npawb rau tom qab taug qab. Ua tiav keeb kwm ntawm tag nrho cov txheej txheem tsim khoom koom nrog hauv cov txheej txheem tsim khoom yog li ua rau kev ruaj ntseg ntawm cov neeg tsim khoom thiab cov neeg siv kawg, cov neeg siv khoom.

CIP

CIP tu cov nroj tsuag (CIP = tu nyob rau hauv qhov chaw) kuj yog ib feem ntawm ib tug niaj hnub margarine chaw txij li thaum margarine ntau lawm nroj tsuag yuav tsum tau ntxuav tsis tu ncua. Rau cov khoom lag luam margarine ib zaug ib lub lim tiam yog lub sijhawm tu ib txwm. Txawm li cas los xij, rau cov khoom rhiab zoo li cov roj tsawg (cov ntsiab lus dej siab) thiab / lossis cov khoom muaj protein ntau, luv luv ntawm CIP raug pom zoo.

Raws li txoj cai, ob lub CIP systems yog siv: CIP cov nroj tsuag uas siv cov tshuaj ntxuav ib zaug xwb los yog cov CIP cov nroj tsuag pom zoo uas ua haujlwm los ntawm cov tshuaj tsis huv ntawm cov ntaub ntawv ntxuav qhov twg cov xov xwm xws li lye, acid thiab / los yog cov tshuaj tua kab mob raug xa rov qab mus rau tus neeg CIP cia tank tom qab siv. Cov txheej txheem tom kawg yog qhov zoo dua vim tias nws sawv cev rau ib puag ncig-phooj ywg kev daws teeb meem thiab nws yog kev daws teeb meem kev lag luam hais txog kev noj cov tshuaj ntxuav thiab ntawm no tus nqi ntawm cov no.

Nyob rau hauv rooj plaub ntau cov kab ntau lawm tau teeb tsa hauv ib lub Hoobkas, nws tuaj yeem teeb tsa kev sib txuas tu lem lossis CIP satellite systems. Qhov no ua rau muaj kev txo qis hauv kev tu lub sijhawm thiab kev siv lub zog. Cov txheej txheem CIP tau txais kev tswj hwm thiab nkag mus rau tom qab kab hauv kev tswj hwm.

TSEEM CEEB

Thaum tsim margarine thiab lwm yam khoom, nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias nws tsis yog tsuas yog cov khoom xyaw xws li cov roj thiab cov rog siv los yog daim ntawv qhia ntawm cov khoom uas txiav txim siab qhov zoo ntawm cov khoom kawg, tab sis kuj yog lub configuration ntawm cov nroj tsuag, cov kev ua thiab lub xeev ntawm cov nroj tsuag. Yog tias cov kab lossis cov khoom siv tsis raug tswj xyuas zoo, muaj kev pheej hmoo tias cov kab yuav tsis ua haujlwm zoo. Yog li ntawd, txhawm rau tsim cov khoom lag luam zoo, cov nroj tsuag ua haujlwm zoo yog qhov yuav tsum tau tab sis kev xaiv ntawm cov roj sib xyaw nrog cov yam ntxwv uas sib haum rau qhov kev thov kawg ntawm cov khoom kuj tseem ceeb nrog rau kev teeb tsa kom raug thiab kev xaiv ntawm cov txheej txheem ntawm cov nroj tsuag. Qhov kawg tab sis tsis kawg qhov kawg cov khoom yuav tsum tau kub-kho raws li kev siv zaum kawg.

Post lub sij hawm: Dec-19-2023