Abstract

Cov margarine ua los ntawm pastry yuav tsum yog yas thiab ruaj khov. Cov txheej txheem ntawm kev tsim cov margarine ua los ntawm pastry tuaj yeem npaj tau yooj yim heev los ntawm tubularchiller (tubular scraped surface heat exchanger). Thaum lub sijhawm ua cov roj tob, kev txias muaj feem cuam tshuam loj heev rau kev ua kom cov margarine ua los ntawm pastry. Cov margarine sib txawv xav tau cov txheej txheem sib txawv thiab cov xwm txheej tempering.

Cov margarine ua los ntawm pastry yuav tsum yog yas thiab ruaj khov. Cov txheej txheem ntawm kev tsim cov margarine ua los ntawm pastry tuaj yeem npaj tau yooj yim heev los ntawm tubularchiller (tubular scraped surface heat exchanger). Thaum lub sijhawm ua cov roj tob, kev txias muaj feem cuam tshuam loj heev rau kev ua kom cov margarine ua los ntawm pastry. Cov margarine sib txawv xav tau cov txheej txheem sib txawv thiab cov xwm txheej tempering.

Cov lus tseem ceeb: pastry margarine; lub nruas txias; tubular chiller, scraped surface heat exchanger, margarine ntau lawm.

Kev taw qhia txog tubular chiller

Txawm hais tias cov khoom lag luam flaky margarine tau tsim tawm ntau xyoo, tib neeg tau sim nrhiav txoj hauv kev zoo tshaj plaws rau cov txheej txheem, feem ntau yog nyob rau ntawm kev sib xyaw ntawm cov mis sib txawv hauv qab cov txheej txheem sib txawv. Ua ntej kev tsim cov tshuab hloov pauv cua sov scraper, lossis lub tshuab quenching raj, txhua yam khoom margarine tau tsim los ntawm kev siv lub tshuab quenching nruas thiab kneading. Vim tias lub tshuab ua quenching raj muaj ntau qhov zoo dua piv rau lwm lub tshuab ua haujlwm, yog li tam sim no cov chaw tsim khoom margarine siv nws cov khoom lag luam ntawm flaky pastry margarine, daim ntawv no ntawm lub tshuab ua quenching raj los tsim cov txheej txheem flaky pastry margarine los ua qee qhov kev qhia.

Cov yam ntxwv tseem ceeb ntawm cov margarine flaky yog nws cov yas thiab ruaj khov. Thaum cov margarine raug tais thiab dov tawm ntau zaus, cov khaubncaws sab nraud povtseg yuav tsum tsis tawg hauv cov khob noom cookie, yog li qhov yas tseem ceeb; Kev ruaj khov kuj tseem ceeb. Yog tias cov margarine tsis khov txaus kom mos lossis roj nkag tau, thiab raug nqus mus rau hauv cov khob noom cookie, cov roj txheej ntawm cov khaubncaws sab nraud povtseg khob noom cookie yuav raug txo qis heev.

Cov qauv ntawm lub tshuab quenching nruas rotary yog qhov yooj yim, tsuas yog xav tau kho ob peb qhov kev teeb tsa hauv kev tsim khoom tuaj yeem tsim cov khoom margarine crisp. Cov flaky pastry margarine tsim los ntawm lub tshuab quenching nruas muaj plasticity zoo, tsis yooj yim rau nkag mus rau hauv roj, thiab ruaj khov heev hauv qhov kub thiab txias loj. Lub tshuab quenching raj dua li lub tshuab quenching nruas hauv kev ua tau zoo tau ua tiav ntau dua, uas feem ntau pom hauv:

(1) Hauv cov khoom ua yeeb nkab kaw, kev sib khi zoo, kev huv huv kuj tseem yuav txhim kho ntau heev;

(2) Kev ua haujlwm siab, uas yog qhov tseem ceeb rau kev tsim cov margarine crisp;

(3) Kev ywj pheej zoo, tuaj yeem hloov pauv qhov ceev, siab, khov zog thiab lwm yam kev ua haujlwm.

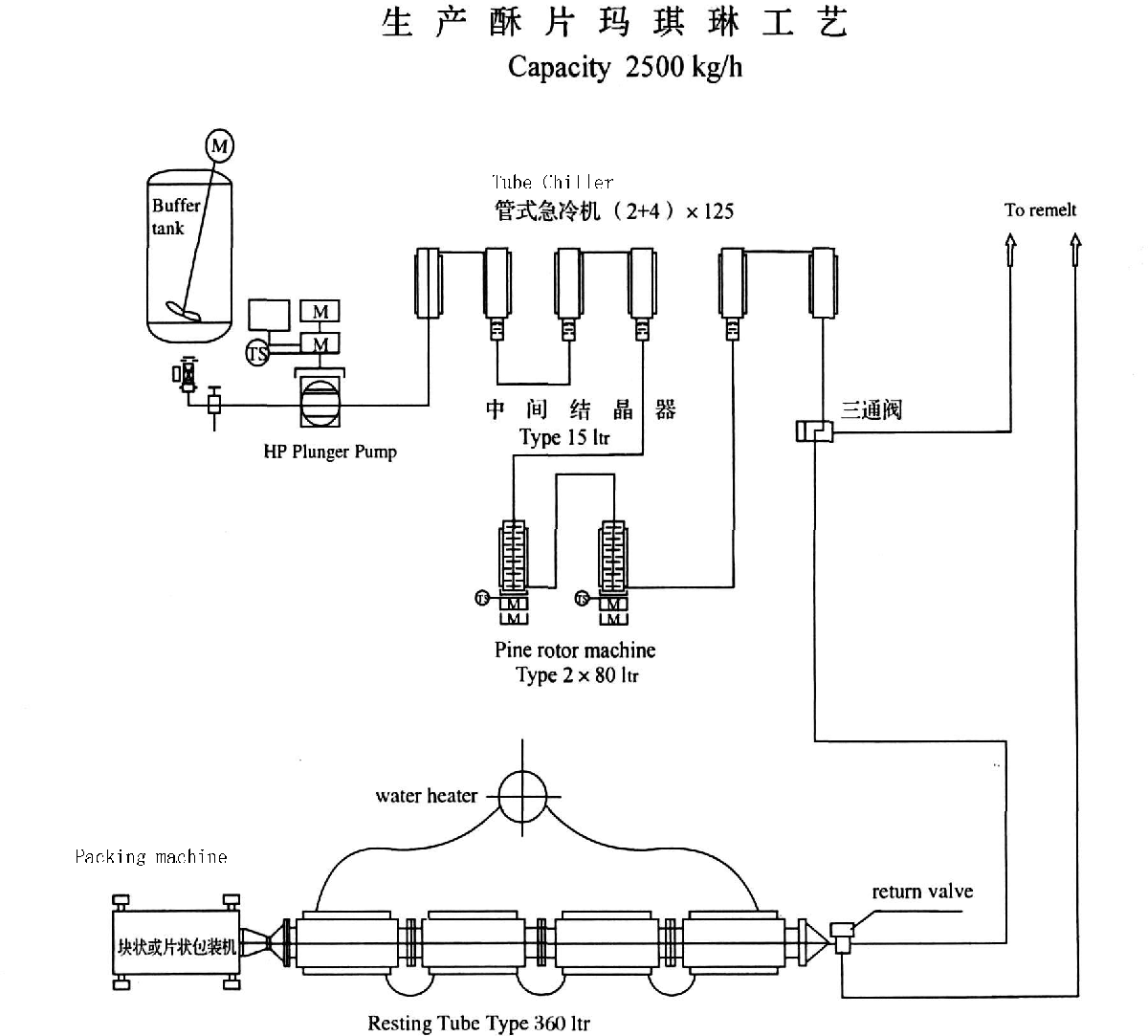

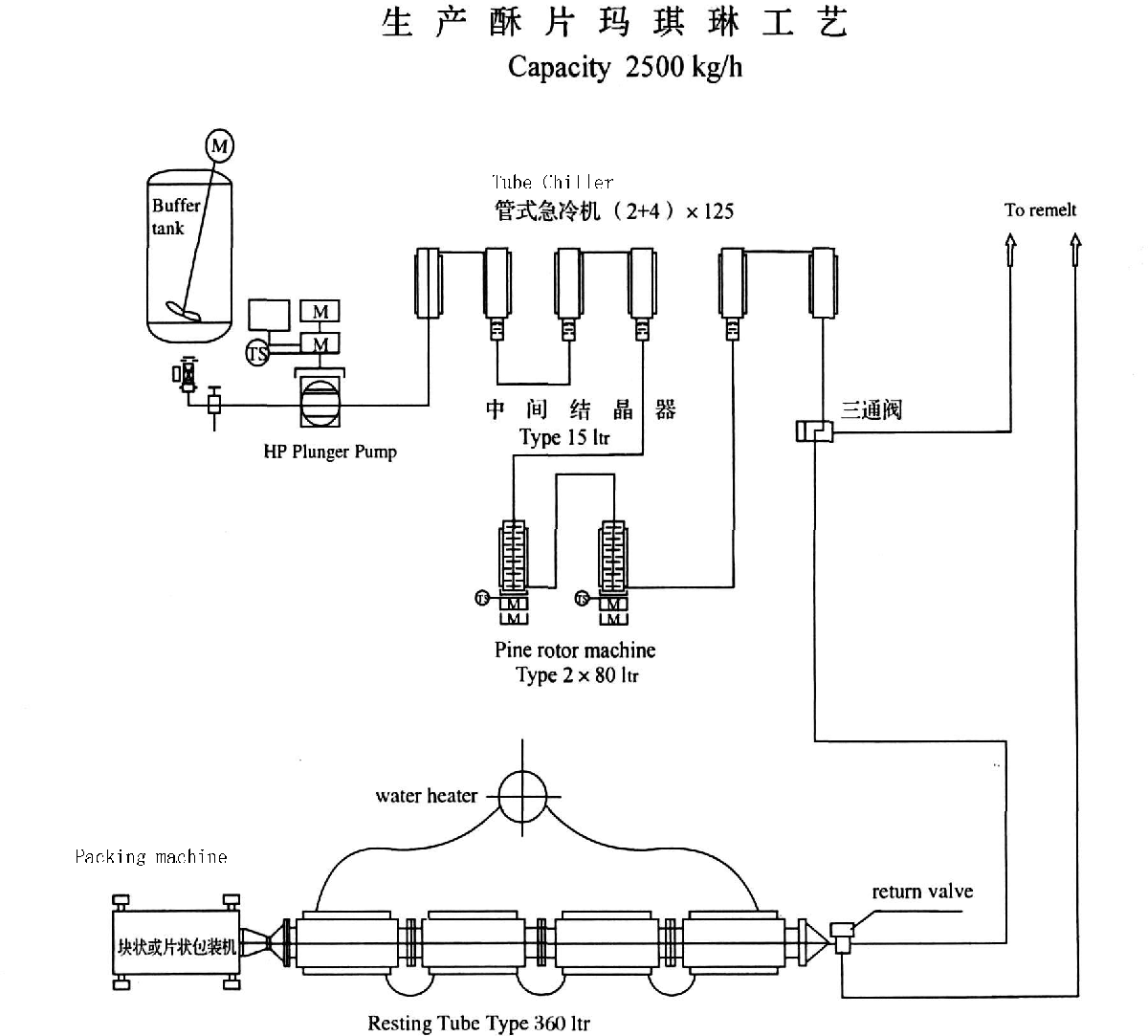

Cov txheej txheem sawv cev rau kev tsim cov flaky pastry margarine los ntawm lub tshuab quenching raj yog raws li nram no:

Lub twj tso kua mis siab siab ※ Lub tshuab hloov cua sov siab (Chav A) ※ Lub tshuab crystallizer nruab nrab ※ Lub tshuab rotor ntoo thuv (Chav B) ※ Lub raj so loj ※ Lub thawv ntim khoom txiav/thaiv.

Lub luag haujlwm ntawm lub tshuab crystallizer nruab nrab yog sib npaug rau ntawm lub tshuab kneader stirring. Nws nyob ntawm lub raj xa dej ntawm lub tshuab ua haujlwm thiab tsav kom tig los ntawm lub tshuab txiav ntawm lub tshuab ua haujlwm.

Nws yooj yim los kho qhov kev ua tiav ntawm cov khoom kom tsim cov khoom qab zib margarine flaky nrog lub tshuab quenching raj. Lub hom phiaj ntawm kev kho cov txheej txheem tuaj yeem ua tiav los ntawm kev hloov hom kev sib txuas ntawm cov yeeb nkab txuas ntawm pawg yeeb nkab quenching (chav A) thiab chav kneading (chav B), uas yooj yim dua rau kev ua haujlwm. Piv txwv li, chav kneading stirring (chav B) tuaj yeem tso rau hauv nruab nrab ntawm cov yeeb nkab quench ntawm chav A, ua raws li qhov ntws ntawm A 1 ※A 2 ※B1 ※B2 ※A 3 ※A 4, lossis hloov mus rau qhov ntws ntawm A 1 ※A 2 ※A 3 ※A 4 ※B1 ※B2. Los ntawm kev hloov pauv cov txheej txheem ua tiav tuaj yeem txhim kho cov khoom zoo. Hauv cov txheej txheem saum toj no, cov txheej txheem ntawm kev tso chav B rau hauv nruab nrab ntawm lub raj quench ntawm chav A yog qhov tsim nyog rau cov roj zaub raws li roj xibtes, uas tau ua pov thawj ntau zaus hauv kev xyaum tsim khoom. Thiab thaum cov khoom tseem ceeb ntawm cov khoom yog nyuj, cov txiaj ntsig zoo dua tuaj yeem tau txais los ntawm kev tso chav B tom qab chav A.

Lub peev xwm kneading yog txiav txim siab los ntawm cov qauv ntawm cov khoom, piv txwv li, lub peev xwm kneading loj dua yuav tsum tau siv rau cov roj formulation nrog qeeb crystallization. Hauv cov txheej txheem tsim cov yeeb nkab txias sai, qhov cuam tshuam kneading yog lub peev xwm ntawm pawg nruab nrab thiab lub peev xwm ntawm crystallizer thiab whip lub chav kneading (B) qhov sib npaug ntawm lub peev xwm ntawm chav, yog li thaum muaj kev hloov pauv hauv cov mis khoom, yuav tsum tau kho lub peev xwm ntawm cov txheej txheem kneading, los ntawm B chav muaj peev xwm nce lossis txo, tuaj yeem nce lossis txo hauv nruab nrab pwm muaj peev xwm, Nws tuaj yeem ua tiav los ntawm kev ntxiv thiab rho tawm tib lub sijhawm, yooj ywm heev.

Lub peev xwm kneading yog txiav txim siab los ntawm cov qauv ntawm cov khoom, piv txwv li, lub peev xwm kneading loj dua yuav tsum tau siv rau cov roj formulation nrog qeeb crystallization. Hauv cov txheej txheem tsim cov yeeb nkab txias sai, qhov cuam tshuam kneading yog lub peev xwm ntawm pawg nruab nrab thiab lub peev xwm ntawm crystallizer thiab whip lub chav kneading (B) qhov sib npaug ntawm lub peev xwm ntawm chav, yog li thaum muaj kev hloov pauv hauv cov mis khoom, yuav tsum tau kho lub peev xwm ntawm cov txheej txheem kneading, los ntawm B chav muaj peev xwm nce lossis txo, tuaj yeem nce lossis txo hauv nruab nrab pwm muaj peev xwm, Nws tuaj yeem ua tiav los ntawm kev ntxiv thiab rho tawm tib lub sijhawm, yooj ywm heev.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-30-2021