Kab Ua Khoom Noj Ncuav Mog Qab Zib Margarine

Kab Ua Khoom Noj Ncuav Mog Qab Zib Margarine

Yees duab tsim tawm:https://www.youtube.com/watch?v=3cSJknMaYd8

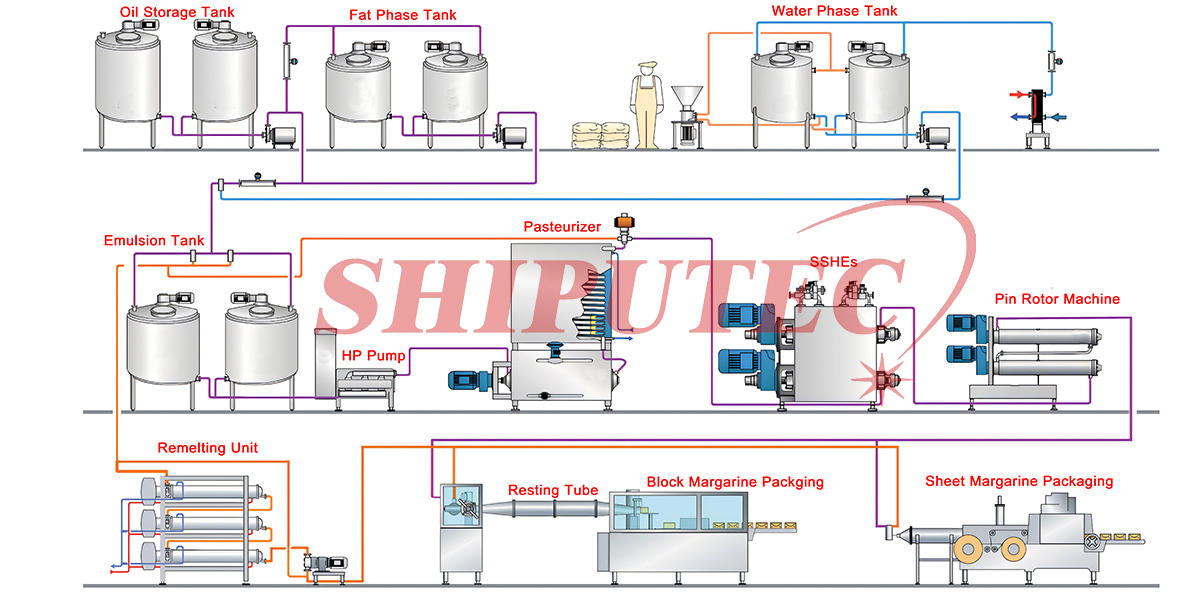

Margarine yog ib yam khoom siv hloov butter uas ua los ntawm roj zaub, roj tsiaj lossis lwm yam roj. Nws cov txheej txheem tsim khoom thiab cov khoom siv ua tiav tau laus heev tom qab ntau xyoo ntawm kev txhim kho. Cov hauv qab no yog cov txheej txheem ntxaws ntxaws thiab kev qhia txog cov khoom siv tseem ceeb:

I. Cov Txheej Txheem Tsim Khoom ntawm Margarin

1. Kev Npaj Khoom Siv Raw

• Cov khoom siv tseem ceeb:

o Cov roj (kwv yees li 80%): xws li roj txiv laum, roj taum pauv, roj rapeseed, roj txiv maj phaub, thiab lwm yam, uas yuav tsum tau ua kom zoo (de-gumming, de-acidification, de-coloring, de-odorization).

o Cov dej theem (kwv yees li 15-20%): mis nyuj skimmed, dej, ntsev, emulsifiers (xws li lecithin, mono-glyceride), preservatives (xws li potassium sorbate), vitamins (xws li vitamin A, D), flavorings, thiab lwm yam.

o Cov Khoom Ntxiv: xim (β-carotene), cov tshuaj tswj acidity (lactic acid), thiab lwm yam.

2. Kev Sib Tov thiab Emulsification

• Kev sib xyaw ua ke ntawm cov roj thiab cov dej:

o Cov roj theem (roj + cov khoom ntxiv uas yaj tau hauv roj) raug cua sov rau 50-60 ℃ thiab yaj.

o Cov dej theem (dej + cov khoom ntxiv uas yaj tau hauv dej) raug cua sov thiab tua kab mob (pasteurization, 72℃/15 vib nas this).

o Ob theem no sib xyaw ua ke raws li qhov sib piv, thiab cov tshuaj emulsifiers (xws li mono-glyceride, soy lecithin) raug ntxiv rau, thiab ib qho emulsion sib xws (dej-hauv-roj lossis roj-hauv-dej) raug tsim los ntawm kev sib xyaw ceev ceev (2000-3000 rpm).

3. Txias sai & crystallization (Kauj Ruam Tseem Ceeb)

• Txias sai: Cov emulsion raug txias sai mus txog 10-20 ℃ los ntawm lub tshuab hloov cua sov ntawm qhov chaw khawb (SSHE), ua rau cov roj crystallization ib nrab los ua β' crystal daim ntawv (qhov tseem ceeb rau cov qauv zoo).

• Kev Ua Pwm: Cov rog ib nrab khov raug txiav los ntawm lub tshuab kneader (Pin Worker) ntawm 2000-3000 rpm kom tawg cov pob zeb loj thiab tsim cov qauv rog zoo thiab sib xws, zam kev xav tias muaj av xuab zeb.

4. Kev Loj Hlob thiab Kev Ntim Khoom

• Kev Loj Hlob: Cia nws sawv ntawm 20-25 ℃ rau 24-48 teev kom ruaj khov cov qauv siv lead ua.

• Ntim: Nws tau ntim ua cov blocks, khob, lossis hom tshuaj tsuag, thiab khaws cia rau hauv lub tub yees (qee cov margarine mos tuaj yeem khaws cia rau hauv chav sov ncaj qha).

II. Cov Khoom Siv Ua Haujlwm Tseem Ceeb

1. Cov Khoom Siv Kho Mob Ua Ntej

• Cov khoom siv ua roj refining: degumming centrifuge, de-acidification tower, de-coloration tank, de-odorization tower.

• Cov khoom siv ua dej theem: tshuab pasteurization, lub tshuab homogenizer siab (siv rau mis nyuj lossis dej theem homogenization).

2. Cov Khoom Siv Emulsification

• Lub tank emulsion: lub tank hlau tsis xeb nrog cov haujlwm nplawm thiab cua sov (xws li lub paddle lossis turbine hom nplawm).

• Lub tshuab ua homogenizer siab: ntxiv cov dej emulsion droplets (siab 10-20 MPa).

3. Cov Khoom Siv Txias Ceev

• Lub Tshuab Hloov Kub Uas Tau Muab Tso Rau Saum Nto (SSHE):

o Txias sai sai kom txog thaum tsis khov, nrog rau rab scraper uas tig tau kom tiv thaiv kev tawg.

o Cov hom lag luam ib txwm muaj: Gerstenberg & Agger (Denmark), Alfa Laval (Sweden), SPX flow (Tebchaws USA), Shiputec (Tuam Tshoj)

• Tus Neeg Ua Haujlwm Pin:

o Txiav cov rog los ntawm ntau pawg ntawm cov pins kom tswj tau qhov loj ntawm cov siv lead ua.

4. Cov Khoom Siv Ntim Khoom

• Tshuab sau tsis siv neeg: rau cov blocks (25g-500g) lossis cov thawv ntim khoom (1kg-20kg).

• Kab ntim khoom uas tsis muaj kab mob: tsim nyog rau cov khoom uas siv tau ntev (xws li cov kua margarine uas kho los ntawm UHT).

III. Cov Txheej Txheem Hloov Pauv

1. Margarine mos: Muaj roj ua kua ntau hauv cov roj (xws li roj paj noob hlis), tsis tas yuav txias sai sai, ncaj qha sib xyaw thiab ntim khoom.

2. Margarine uas muaj roj tsawg: Muaj roj 40-60%, yuav tsum tau ntxiv cov tshuaj ua kom tuab (xws li gelatin, hmoov txhuv nplej hloov kho).

3. Margarine ua los ntawm cov nroj tsuag: Cov mis roj uas yog los ntawm cov nroj tsuag, tsis muaj cov roj trans fatty acids (kho qhov melting point los ntawm kev pauv ester lossis fractionation technology).

IV. Cov Ntsiab Lus Tseem Ceeb ntawm Kev Tswj Xyuas Zoo •

Cov qauv siv lead ua: Cov qauv siv lead ua β' (zoo dua li cov qauv siv lead ua β) yuav tsum tau tswj hwm qhov nrawm thiab qhov sib xyaw ua ke.

• Kev nyab xeeb ntawm cov kab mob me me: Cov dej hauv av yuav tsum tau ua kom huv si, thiab pH yuav tsum tau kho kom qis dua 4.5 kom tiv thaiv cov kab mob me me.

• Kev ruaj khov ntawm oxidation: Ntxiv cov tshuaj antioxidants (xws li TBHQ, vitamin E) kom tsis txhob muaj kev sib kis ntawm cov hlau ion.

Los ntawm kev sib xyaw ua ke ntawm cov txheej txheem thiab cov khoom siv saum toj no, cov tshuaj pleev niaj hnub tuaj yeem ua rau saj ntawm butter thaum ua tau raws li cov kev xav tau kev noj qab haus huv xws li cov roj cholesterol tsawg thiab cov rog tsawg. Cov mis tshwj xeeb thiab cov txheej txheem yuav tsum tau hloov kho raws li qhov chaw ntawm cov khoom (xws li rau kev ci lossis rau kev siv rau ntawm cov khoom noj).

Kev Ua Haujlwm ntawm Qhov Chaw