Chav Sib Hloov Kub Nto Uas Tau Khawb Tawm Qauv SPVU Tuam Tshoj Chaw Muag Khoom

Tuam Tshoj Scraped Surface Heat Exchanger & Votator Chaw Tsim Khoom thiab Chaw Muag Khoom. Peb lub tuam txhab muaj Tuam Tshoj Scraped Surface Heat Exchanger & Votator muag, txais tos hu rau peb.

Yees duab tsim tawm:https://www.youtube.com/watch?v=AkAcycJx0pI

Daim Ntawv Thov

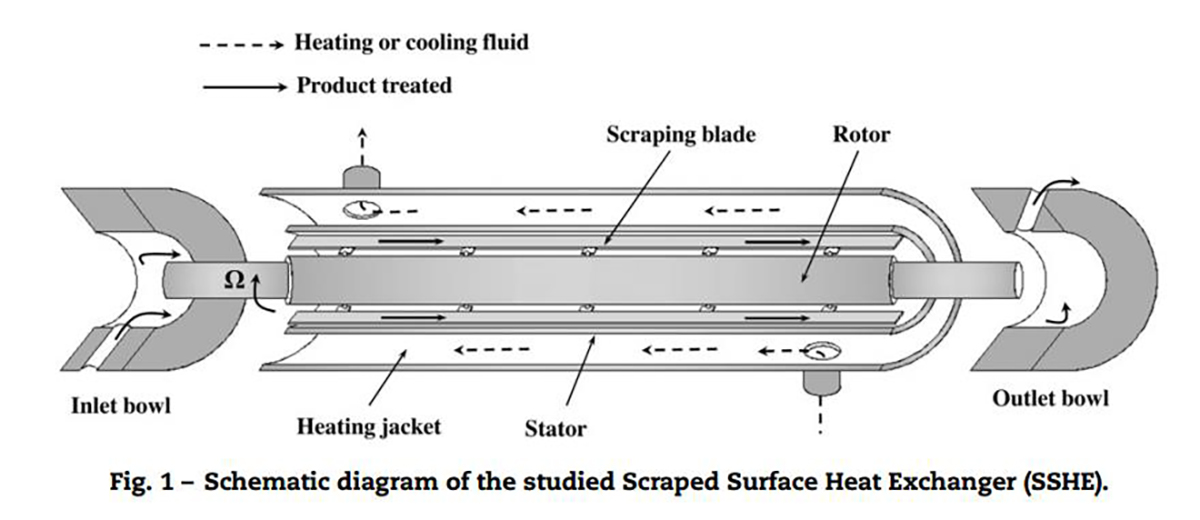

SPVU series scraper heat exchanger unit yog ib hom tshiab ntawm scraper heat exchanger, siv tau los ua kom sov thiab txias ntau yam khoom viscosity, tshwj xeeb tshaj yog rau cov khoom tuab thiab viscous heev, nrog rau qhov zoo, kev noj qab haus huv nyiaj txiag, kev ua haujlwm hloov pauv cua sov siab, thiab cov yam ntxwv pheej yig.

• Kev tsim qauv me me

• Kev sib txuas ntawm lub spindle ruaj khov (60mm)

• Qhov zoo thiab thev naus laus zis ntawm lub tshuab scraper uas ruaj khov

• Kev siv tshuab ua kom raug siab

• Cov khoom siv hloov pauv cua sov khov kho thiab kev ua cov qhov sab hauv

• Lub tog raj kheej hloov cua sov tuaj yeem tshem tawm thiab hloov pauv nyias

• Kev sib koom ua ke ntawm lub cev muaj zog tsav iav - tsis muaj cov txuas, siv sia lossis pulley

• Kev teeb tsa ncej concentric lossis eccentric

• Ua raws li GMP, CFIA, 3A thiab ASME cov qauv tsim, FDA xaiv tau

Cov khoom ua tiav los ntawm SSHEs.

Lub tshuab hloov cua sov scraper siv tau rau yuav luag txhua txoj kev txuas ntxiv mus rau kev nqus cov kua dej lossis cov kua dej khov, thiab tuaj yeem muaj cov ntawv thov hauv qab no:

Kev lag luamdaim ntawv thov nyiaj txiag

Kev ua cua sov

Kev txias tsis muaj kab mob

Kev txias txias

Kev ua kom muaj pob zeb

Kev tua kab mob.

Kev ua kom qhuav

Jelling

Kev Piav Qhia Txog Khoom Siv

Cov khoom rau SPVU scraper heat exchangers tuaj yeem tsim tau ntau yam kev teeb tsa thiab cov ntaub ntawv, yog li txhua lub tshuab hloov pauv cua sov tuaj yeem kho kom haum rau cov txheej txheem tshwj xeeb ntawm txhua daim ntawv thov. Cov khoom ua raws li GMP, CFIA, 3A thiab ASME tus qauv tsim thiab tuaj yeem muab daim ntawv pov thawj FDA.

• Lub zog tsav tsheb los ntawm 5.5 txog 22kW

• Ntau yam kev ceev ntawm cov zis (100 ~ 350 r / min)

• Cov hlau carbon uas muaj chromium-nickel-plated thiab 316 stainless hlau cua sov hloov cov raj tsim los rau kev hloov cua sov zoo dua

• Tus qauv stainless hlau los yog yas scraper, kev cai yas scraper uas tuaj yeem ntes hlau

• Qhov loj ntawm lub spindle raws li cov yam ntxwv ntawm cov kua (120, 130 thiab 140mm)

• Ib lossis ob lub foob pob hluav taws xob yog xaiv tau

Dielectric interlayer

Dielectric interlayers ntawm scraper heat exchangers rau kua, pa lossis ncaj qha expansion refrigeration

Lub tsho loj siab ntawm dielectric sandwich

232 psi (16 MPa) @ 400° F (204° C) los yog 116 psi (0.8MPa) @ 400° F (204° C)

Siab Sab Khoom. Siab sab khoom

435 psi (3MPa) @ 400° F (204° C) los yog 870 psi (6MPa) @ 400° F (204° C)

Lub tog raj kheej hloov cua sov

• Kev ua kom sov thiab phab ntsa tuab yog qhov tseem ceeb uas yuav tsum xav txog thaum xaiv cov raj xa cua sov. Lub phab ntsa tuab ntawm lub tog raj kheej yog tsim los kom txo qhov kev tiv thaiv cua sov thaum ua kom ruaj khov ntawm cov qauv.

• Lub tog raj kheej nickel ntshiab uas muaj kev ua kom sov siab. Sab hauv ntawm lub tog raj kheej yog plated nrog chrome tawv thiab tom qab ntawd zom thiab txhuam kom du kom tiv taus kev txhuam los ntawm cov khawb thiab cov khoom sib tsoo.

• Cov kav hlau carbon uas muaj chromium-plated muab kev ua kom sov siab ntawm tus nqi tsim nyog rau cov khoom xws li txiv laum huab xeeb, shortening thiab margarine.

• Cov kav hlau tsis xeb uas tsim tshwj xeeb los txhim kho kev hloov pauv cua sov rau cov khoom siv acidic thiab muab kev ywj pheej hauv kev siv cov tshuaj ntxuav.

strickle

Cov cuab yeej khawb tau teeb tsa ua kab sib dhos rau ntawm tus pas. Lub cuab yeej khawb tau ruaj khov rau ntawm tus pas ntawm lub tshuab hloov pauv cua sov los ntawm lub "pin universal" uas ruaj khov, tsim tshwj xeeb. Cov pins no tuaj yeem tshem tawm sai thiab yooj yim thiab hloov lub cuab yeej khawb.

lub foob

Cov foob pob hluav taws xob tau tsim tshwj xeeb kom yooj yim sib dhos thiab tswj, thiab kom ntseeg tau tias kev ua haujlwm txhim khu kev qha.

Qhov ceev ntawm cov khoom cua sov thiab lub sijhawm nyob hauv lub tshuab hloov cua sov raug tswj los ntawm qhov ntim ntawm cov khoom siv. Cov tshuab hloov cua sov nrog cov ncej me me muab cov qhov sib txawv loj thiab lub sijhawm nyob ntev, thiab tuaj yeem tswj cov khoom loj thiab cov khoom nrog cov khoom me me. Cov tshuab hloov cua sov nrog cov ncej loj muab cov qhov sib txawv me me rau qhov ceev ceev thiab kev co, thiab muaj cov nqi hloov cua sov siab dua thiab lub sijhawm nyob luv dua ntawm cov khoom.

Tsav tsheb

Kev xaiv lub cev muaj zog tsav tsheb rau lub tshuab hloov cua sov scraper muab kev ua tau zoo tshaj plaws hauv txhua daim ntawv thov, kom ntseeg tau tias cov khoom raug do kom zoo thiab khawb tas li ntawm phab ntsa hloov cua sov. Lub tshuab hloov cua sov scraper muaj lub cev muaj zog tsav tsheb ncaj qha nrog ntau txoj kev xaiv fais fab los muab kev ua tau zoo tshaj plaws rau cov ntawv thov tshwj xeeb.

Khoom siv cua sov

Cov khoom uas lwj vim raug cua sov ntev tuaj yeem kho tau zoo hauv cov khoom siv hloov cua sov scraper. Lub scraper tiv thaiv cov khoom kom tsis txhob nyob ntawm qhov chaw hloov cua sov los ntawm kev tshem tawm thiab rov ua dua daim zaj duab xis tas li. Vim tias tsuas yog me me ntawm cov khoom raug rau ntawm qhov chaw kub dhau rau lub sijhawm luv luv, kev kub hnyiab tuaj yeem txo qis lossis tshem tawm kom tsis txhob muaj coking.

Khoom nplaum

Cov khoom sib pauv cua sov uas siv lub tshuab khawb (scraper heat exchangers) ua haujlwm tau zoo dua li cov khoom sib pauv cua sov uas siv lub phaj lossis lub raj. Cov zaj duab xis ntawm cov khoom raug khawb tas li ntawm phab ntsa hloov cua sov kom tsim tau cov cua sov hloov siab heev. Kev sib xyaw tas li yuav ua rau muaj kev kub ntxhov, ua rau cua sov lossis cua txias sib npaug zoo dua; Qhov siab poob tuaj yeem tswj tau zoo los ntawm thaj chaw ntawm cov khoom; Kev sib xyaw tuaj yeem tshem tawm cov chaw tsis txav thiab cov khoom sib sau ua ke; Thiab nws yooj yim dua los ntxuav.

Cov khoom me me

Hauv cov khoom siv hloov cua sov scraper, nws yooj yim rau kev tswj cov khoom uas muaj cov khoom me me uas feem ntau txhaws cov khoom siv hloov cua sov ib txwm muaj, qhov teeb meem uas zam tau hauv cov khoom siv hloov cua sov scraper.

Cov khoom siv lead ua

Cov khoom siv crystallized zoo tagnrho rau kev ua cov khoom siv hloov cua sov scraper. Cov khoom siv crystallizes rau ntawm phab ntsa hloov cua sov, thiab lub scraper tshem tawm nws thiab ua kom qhov chaw huv. Qhov degree supercooling zoo thiab kev co muaj zog tuaj yeem tsim cov nucleus crystal zoo.

Kev Ua Tshuaj Lom Zem

Cov kev lag luam tshuaj lom neeg, tshuaj thiab petrochemical tuaj yeem siv cov khoom sib pauv cua sov scraper hauv ntau cov txheej txheem, uas tuaj yeem faib ua plaub pawg dav.

1. Kev Ua Kub thiab Txias: Rau cov khoom sib pauv cua sov scraper, kev tuav cov khoom nplaum heev tsis yog teeb meem. Khawb cov zaj duab xis khoom ntawm qhov chaw ntawm cov yeeb nkab cua sov lossis cov yeeb nkab txias ntau zaus hauv ib feeb kom tiv thaiv kev tsim cov nplai lossis txheej khov kom tiv thaiv kev hloov pauv cua sov ntxiv. Tag nrho cov khoom ntws thaj chaw loj, yog li qhov poob siab tsawg heev.

2. Kev Siv Crystallization: Lub tshuab hloov cua sov scraper siv tau ua lub tshuab txias kom txias cov khoom siv mus rau qhov kub qis dua, thaum ntawd cov solute pib siv crystallize. Kev ncig mus los ntawm lub tshuab hloov cua sov ntawm qhov nrawm siab ua rau muaj cov nuclei siv lead ua, uas loj hlob sib cais tom qab mus txog qhov kub kawg. Cov quav ciab thiab lwm yam khoom kho tag nrho tuaj yeem txias mus rau qhov chaw yaj hauv ib zaug ua haujlwm, tom qab ntawd sau rau hauv pwm, tso rau ntawm daim kab txias lossis granulated siv lwm yam khoom siv.

3. Kev tswj cov tshuaj tiv thaiv: cov khoom siv hloov cua sov scraper tuaj yeem siv los tsav cov tshuaj tiv thaiv los ntawm kev tswj cov cua sov. Rau cov tshuaj tiv thaiv exothermic, cov khoom siv hloov cua sov tuaj yeem tshem tawm cov cua sov tiv thaiv kom tsis txhob muaj kev puas tsuaj ntawm cov khoom lossis cov tshuaj tiv thaiv tsis zoo. Lub tshuab hloov cua sov tuaj yeem ua haujlwm ntawm qhov siab heev ntawm 870 psi (6MPa).

4. Cov khoom uas tau nplawm/nthuav cua:

Lub tshuab hloov cua sov scraper xa cov nyhuv sib xyaw zoo rau cov khoom thaum nws ntws raws txoj kab tig, yog li cov roj tuaj yeem sib xyaw rau hauv cov khoom thaum ua kom sov lossis txias. Cov khoom ua kom cua tuaj yeem ua los ntawm kev ntxiv roj es tsis txhob cia siab rau cov tshuaj lom neeg los tsim cov npuas ua cov khoom seem.

Cov Kev Siv Ib Txwm ntawm SSHEs

Cov khoom siv viscosity siab

Surimi, kua txiv lws suav, kua custard, kua chocolate, cov khoom whipped/aerated, txiv laum huab xeeb butter, mashed potatoes, starch paste, sandwich sauce, gelatin,

Nqaij minced tsis muaj pob txha, khoom noj menyuam yaus, nougat, tshuaj pleev tawv nqaij, tshuaj zawv plaub hau, thiab lwm yam

Cov khoom siv kub rhiab heev

Cov khoom ua kua qe, kua zaub, txiv hmab txiv ntoo npaj, cheese qab zib, whey, kua ntses taum pauv, kua protein, ntses txiav, thiab lwm yam

Crystallization thiab theem hloov pauv

Qab zib concentrate, margarine, shortening, lard, fudge, solvents, fatty acids, petroleum jelly, npias thiab cawv txiv hmab, thiab lwm yam

Cov khoom siv granular

Nqaij minced, nqaij qaib nuggets, ntses hmoov, khoom noj tsiaj, khoom qab zib, txiv hmab txiv ntoo yogurt, cov khoom xyaw txiv hmab txiv ntoo, ncuav mog qab zib, smoothies, pudding, zaub slices, Lao Gan Ma, thiab lwm yam

Cov khoom siv viscous

Caramel, cheese sauce, lecithin, cheese, khoom qab zib, poov xab extract, mascara, tshuaj txhuam hniav, wax, thiab lwm yam

Kev Qhia Txog Kev Siv

| Qauv | Thaj Chaw Nto ntawm Lub Tshuab Hloov Kub | Qhov Chaw Annular | Qhov Ntev ntawm Lub Raj | Qhov ntau ntawm cov khoom siv khawb | Qhov Loj | Lub zog | Siab Tshaj Plaws | Qhov Ceev Ntawm Lub Ncej Tseem Ceeb |

| Chav tsev | M2 | mm | mm | pc | mm | kw | Mpa | rpm |

| SPV18-220 | 1.24 | 10-40 | 2200 | 16 | 3350 * 560 * 1325 | 15 los yog 18.5 | 3 los yog 6 | 0-358 |

| SPV18-200 | 1.13 | 10-40 | 2000 xyoo | 16 | 3150 * 560 * 1325 | 11 los yog 15 | 3 los yog 6 | 0-358 |

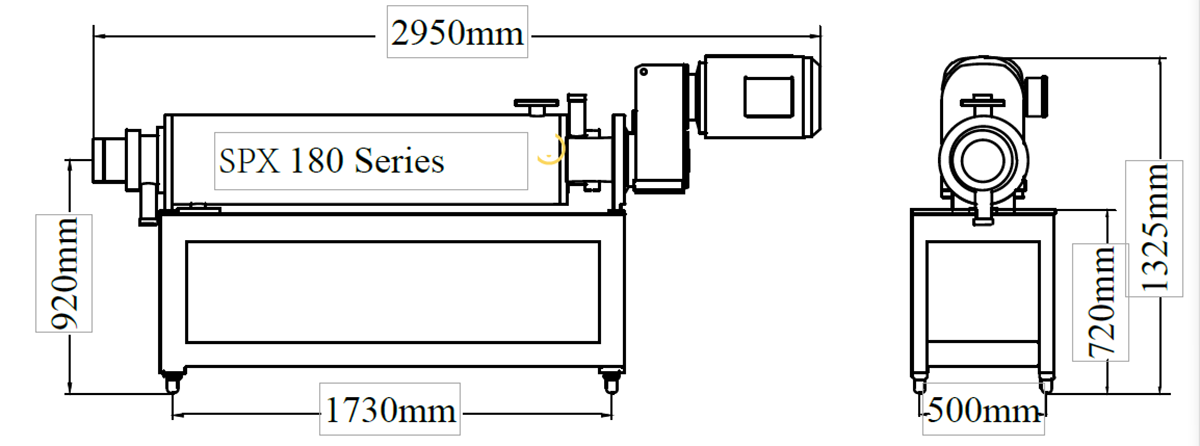

| SPV18-180 | 1 | 10-40 | 1800 xyoo | 16 | 2950 * 560 * 1325 | 7.5 los yog 11 | 3 los yog 6 | 0-340 |

| SPV15-220 | 1.1 | 11-26 | 2200 | 16 | 3350 * 560 * 1325 | 15 los yog 18.5 | 3 los yog 6 | 0-358 |

| SPV15-200 | 1 | 11-26 | 2000 xyoo | 16 | 3150 * 560 * 1325 | 11 los yog 15 | 3 los yog 6 | 0-358 |

| SPV15-180 | 0.84 | 11-26 | 1800 xyoo | 16 | 2950 * 560 * 1325 | 7.5 los yog 11 | 3 los yog 6 | 0-340 |

| SPV18-160 | 0.7 | 11-26 | 1600 xyoo | 12 | 2750 * 560 * 1325 | 5.5 los yog 7.5 | 3 los yog 6 | 0-340 |

| SPV15-140 | 0.5 | 11-26 | 1400 | 10 | 2550 * 560 * 1325 | 5.5 los yog 7.5 | 3 los yog 6 | 0-340 |

| SPV15-120 | 0.4 | 11-26 | 1200 | 8 | 2350 * 560 * 1325 | 5.5 los yog 7.5 | 3 los yog 6 | 0-340 |

| SPV15-100 | 0.3 | 11-26 | 1000 | 8 | 2150 * 560 * 1325 | 5.5 | 3 los yog 6 | 0-340 |

| SPV15-80 | 0.2 | 11-26 | 800 | 4 | 1950 * 560 * 1325 | 4 | 3 los yog 6 | 0-340 |

| SPV-Lab | 0.08 | 7-10 | 400 | 2 | 1280 * 200 * 300 | 3 | 3 los yog 6 | 0-1000 |

| SPT-Max | 4.5 | 50 | 1500 xyoo | 48 | 1500 * 1200 * 2450 | 15 | 2 | 0-200 |

| Lus Cim: Tus qauv Siab Siab tuaj yeem muab qhov chaw siab txog li 8MPa (1160PSI) nrog lub zog tsav ntawm 22KW (30HP) | ||||||||

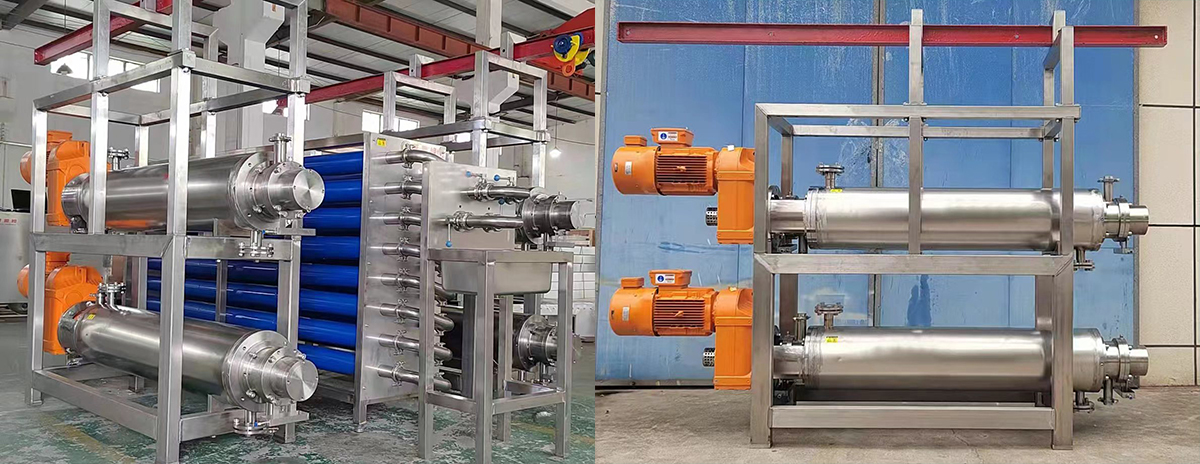

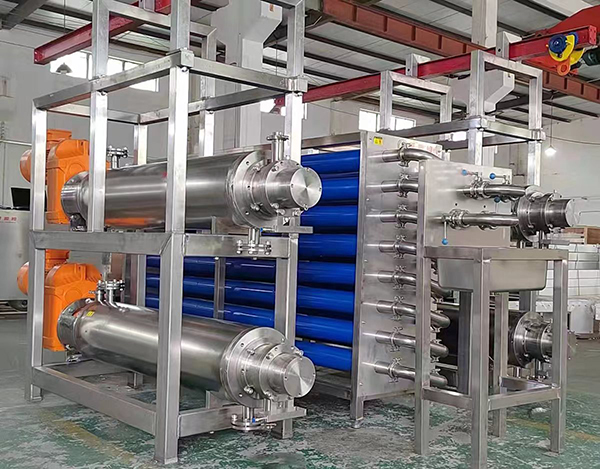

Duab Khoom Siv

Kev Kos Duab Khoom Siv

Kev Ua Haujlwm ntawm Qhov Chaw