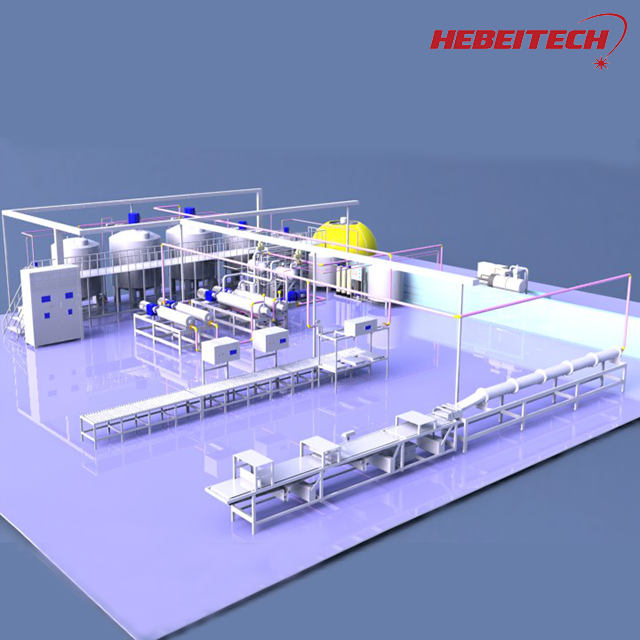

Shortening/Ghee Production Line Tuam Tshoj Chaw tsim tshuaj paus

Shortening & Ghee Production Line

Shortening thiab Ghee yog nrov heev nyob rau hauv kev lag luam bakery, cov khoom raw muaj xws li xibtes roj, zaub roj, tsiaj rog, ib nrab hydrogenated roj thiab rog, marine roj, xibtes kernel roj, lard, nqaij nyuj tallow, xibtes stearin, txiv maj phaub roj, thiab lwm yam.

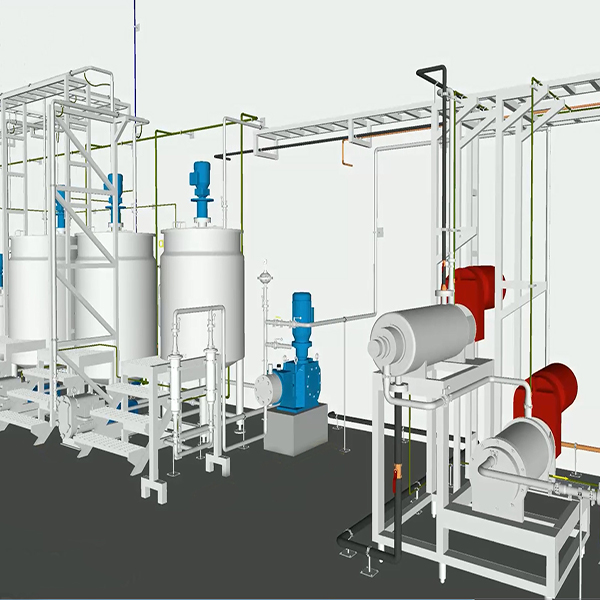

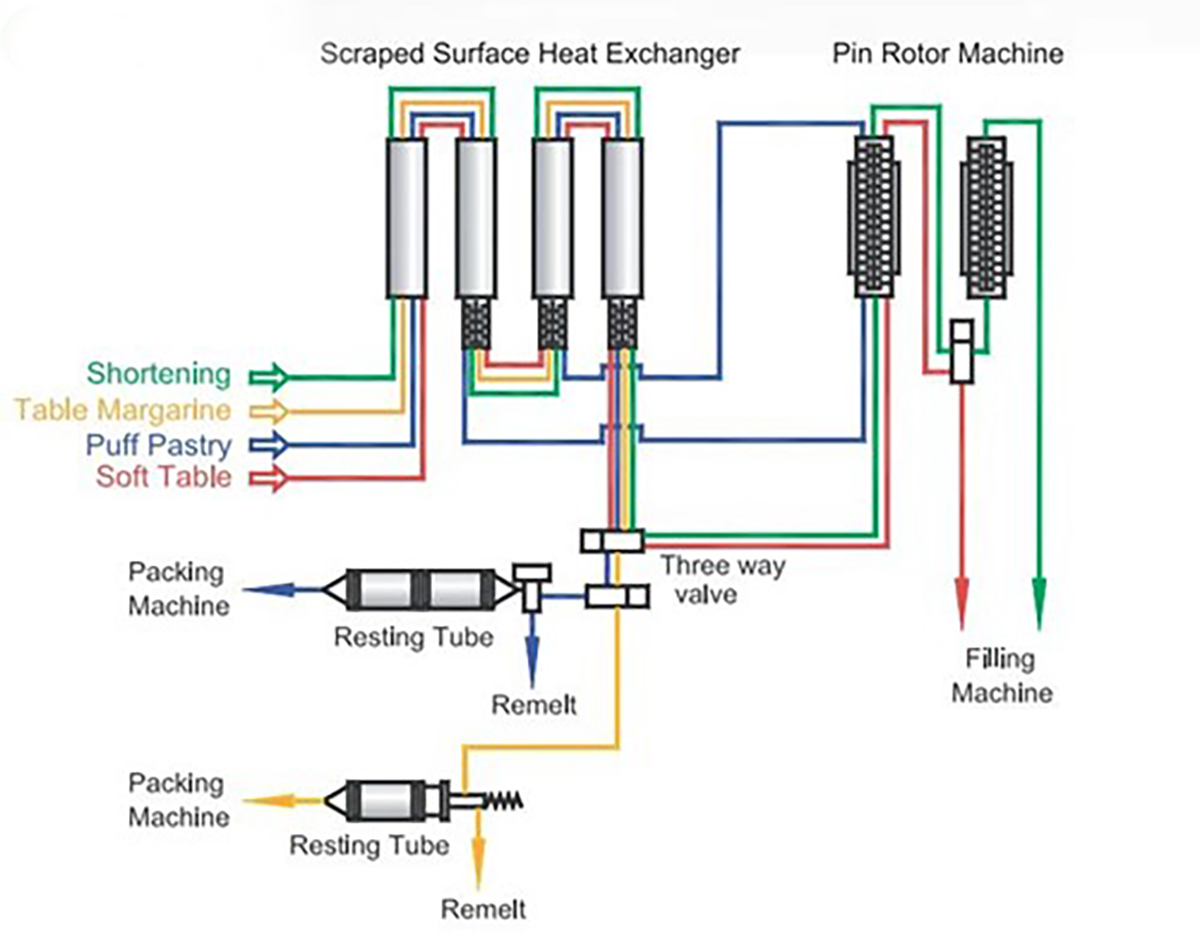

Lub ntsiab shortening txheej txheem yog ntsuas - Cov khoom xyaw Proportion - Lim - Emulsification - Crystalization - Pin Rotor Kneading - Sau & Packing.Cov khoom siv uas ua rau Shortening ntau lawm cog suav nrog Votators, Scraped Surface Heat Exchanger, Kneader, Pin Rotor, shortening filling thiab packing tshuab, homogenizer, emulsifying tank, batching tank, siab siab twj tso kua mis, sterilizer, tub yees compressor, tub yees chav tsev, cua txias pej thuam, etc.

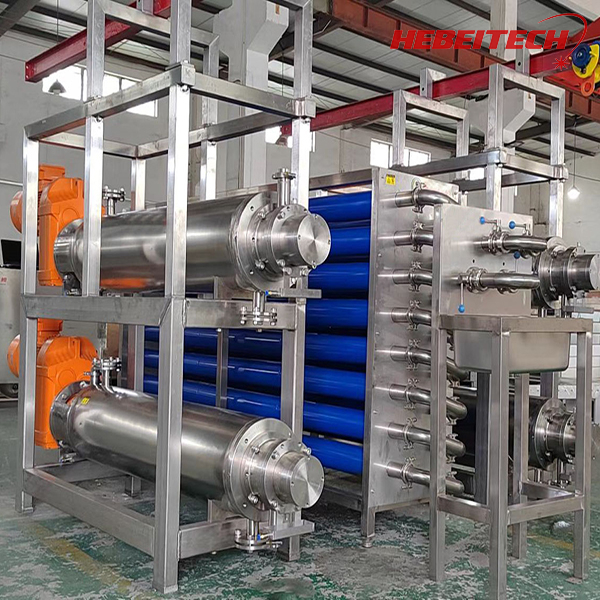

Nyob qhov twg, SPA + SPB + SPC units los yog SPX-Plus + SPB + SPCH units tsim ib tug shortening crystallization kab, uas yuav ua tau shortening, zaub ghee thiab lwm yam butter khoom.

Cov qauv ntawm SPA Series SSHE Shortening ua tshuab yog qhov tshwj xeeb.Tom qab ntau xyoo optimization, nws muaj cov cuab yeej siv siab ruaj khov, qhov zoo thiab ua tiav ntawm cov khoom luv luv yog ua nyob rau hauv Suav teb.

Feem ntau, SP series margarine / luv luv (ghee) txheej txheem yog:

1. Roj thiab Fat blends thiab aqueous theem yog pre-weighed nyob rau hauv ob emulsion tuav thiab sib tov hlab ntsha.Kev sib xyaw ua ke hauv o lub tuav / sib tov cov hlab ntsha yog ua los ntawm cov hlwb uas tswj los ntawm PLC tswj qhov system.

2. Kev sib xyaw ua ke yog tswj los ntawm lub tshuab computer logical nrog lub vijtsam kov.Txhua qhov sib xyaw / ntau lub tank yog nruab nrog lub tshuab shear siab kom emulsify cov roj thiab aqueous theem.

3. Lub tshuab tov khoom yog nruab nrog kev sib txawv ntawm kev tsav tsheb kom txo tau qhov ceev kom maj mam agitation tom qab emulsification tiav.Ob lub tso tsheb hlau luam yuav raug siv los ua lub tank ntau lawm thiab emulsification tank hloov.

4. Lub tank ntau lawm kuj tseem ua haujlwm raws li cov khoom siv rov ua dua tshiab los ntawm cov kab ntau lawm.Lub tank ntau lawm yuav yog lub tank dej / tshuaj lom neeg rau kev tu kab thiab kev huv.

5. Lub emulsion los ntawm lub tank ntau lawm yuav dhau los ntawm ob lub lim / lim kom paub tseeb tias tsis muaj cov khoom yuav dhau los ntawm cov khoom kawg (GMP yuav tsum tau ua).

6. Lub lim/strainer ua haujlwm rau kev lim dej.Cov emulsion lim tau dhau los ntawm pasteurizer (GMP qhov yuav tsum tau ua) uas muaj peb ntu ntawm ob lub phaj cua sov thiab ib lub yeeb nkab tuav.

7. Thawj lub phaj rhaub yuav ua kom sov cov roj emulsion mus rau pasteurization kub ua ntej dhau los ntawm cov yeeb nkab tuav kom muab lub sijhawm tuav tsim nyog.

8. Txhua yam emulsion cua sov kom tsawg dua li qhov yuav tsum tau ua kom sov pasteurization yuav rov qab mus rau lub tank ntau lawm.

9 Cov roj pasteurized emulsion yuav nkag mus rau hauv lub phaj cua txias cua sov kom txias kom txog li 5 ~ 7-degree C saum cov roj melting point kom txo qis zog chilling.

10. Lub phaj rhaub cua sov yog cua sov los ntawm cov dej kub nrog kev tswj kub.Lub phaj txias yog ua los ntawm cov dej txias ntauwd nrog tsis siv neeg kub tswj valve thiab PID loops.

11. Lub emulsion twj tso kua mis / hloov, mus txog qhov no, yog ua los ntawm ib lub twj tso kua mis siab.Lub emulsion yog pub rau hauv Votator chav tsev thiab tus pin rotor hauv kev txiav txim sib txawv, tom qab ntawd txo qhov kub thiab txias rau qhov kub uas xav tau los tsim cov margarine / luv cov khoom xav tau.

12. Cov roj ib nrab tuaj yeem tawm ntawm lub tshuab votator yuav ntim lossis ntim los ntawm margarine shortening filling thiab ntim tshuab.

Tus nqi zoo tshaj ntawm Votators

Txij li thaum xyoo 2004, ShiPU Machinery tau tsom mus rau thaj chaw ntawm cov khoom siv hluav taws xob sib cais.Peb scraped nto tshav kub exchangers muaj lub koob npe nrov thiab lub koob npe nrov nyob rau hauv Asia lag luam.Shipu Machinery tau ntev tau muab cov nqi zoo tshaj plaws rau kev lag luam bakery, kev lag luam khoom noj khoom haus thiab kev lag luam khoom noj siv mis, xws li Fonterra pab pawg, Wilmar pawg, Puratos, AB Mauri thiab lwm yam. Peb cov khoom siv hluav taws xob hluav taws xob hluav taws xob yog li 20%-30% xwb. ntawm cov khoom zoo sib xws hauv Tebchaws Europe thiab Asmeskas, thiab tau txais tos los ntawm ntau lub hoobkas.Cov chaw tsim khoom siv cov khoom zoo thiab pheej yig SP series scraped nto tshav kub exchangers ua nyob rau hauv Tuam Tshoj kom sai li sai tau ntau lawm muaj peev xwm thiab txo cov nqi ntau lawm, cov khoom uas tsim los ntawm lawv lub Hoobkas muaj zoo heev kev lag luam kev sib tw thiab tus nqi zoo, ceev ceev nyob rau hauv feem ntau cov lag luam feem.

Cov chaw tsim khoom noj khoom haus los ntawm thoob plaws lub ntiaj teb zoo siab txais tos yuav cov khoom siv hluav taws xob hluav taws xob ncaj qha los ntawm SP Machinery, thiab cov tuam txhab tsim khoom, kev teeb tsa thiab cov tuam txhab engineering kuj txais tos los ua peb tus neeg sawv cev.Peb muab cov khoom zoo thiab pheej yig scraped nto tshav kub exchanger nrog tus nqi zoo tshaj.

Site Commissioning